9 Essential Warehouse Safety Tips – [With Checklist]

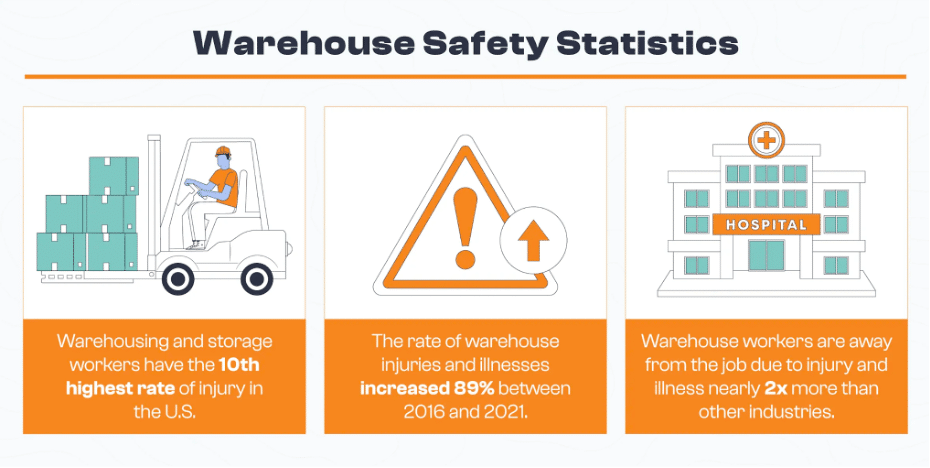

If you own, operate, or work in a warehouse, understanding safety measures is essential. According to the U.S. Department of Labor, warehousing and storage workers have the tenth-highest rate of injury in the United States. Despite the warehouse industry growing by 14% between 2016 and 2021, the number of injuries and illnesses among workers disproportionately increased by 89%. Warehouse workers also required nearly twice the number of days away from the job due to injury and illness compared to other types of workers.

The risks that warehouse employees face range from fire dangers to hazardous chemicals. However, the most common injuries are musculoskeletal disorders (mainly from lifting and lowering) or being struck by material handling equipment (including forklifts). While no Occupational Safety and Health Administration (OSHA) standards specifically control warehousing, you should follow the agency’s general industry safety requirements to protect both employees and employers.

We offer OSHA-compliant training courses for warehouse workers on a wide variety of topics, from our general Warehouse Safety Orientation to videos on specific pieces of equipment, such as our Straddle Stacker Safety Training. In this post, we cover common warehouse safety tips, what you can do to prevent issues, and how to promote a safe work environment within the warehouse.

9 Best Practices for Preventing Warehouse Accidents

Whether you own or work in a warehouse, safety should be your top priority. Here are some best practices for preventing warehouse accidents from occurring, protecting both personal safety and your company’s reputation.

1. Follow All Relevant Standards

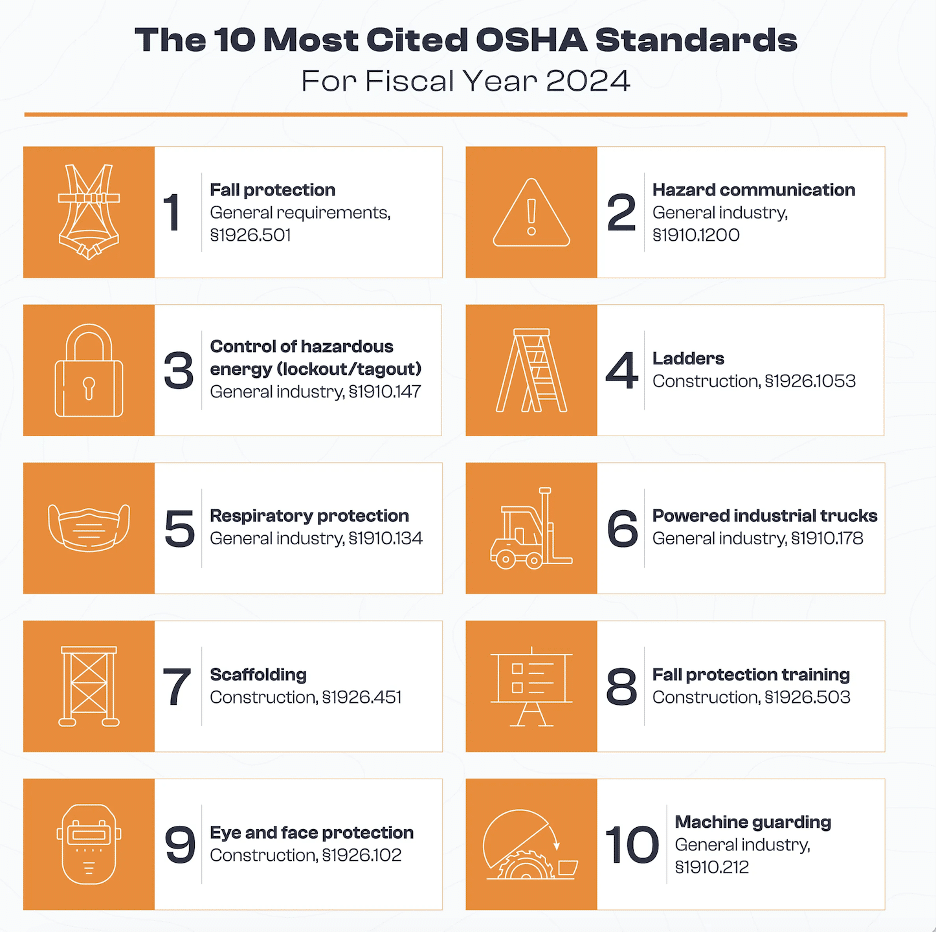

First, you should begin your safety program by researching the applicable OSHA standards. By making sure your warehouse operations meet OSHA standards, you can prevent accidents and costly fines or violations. While OSHA has no warehouse-specific standards, most aspects of warehouse safety are addressed through OSHA’s general industry guidelines 29 Code of Federal Regulations (CFR) 1910, which include the following:

- 1910 Subpart D – Walking-Working Surfaces

- 1910 Subpart E – Exit Routes and Emergency Planning

- 1910 Subpart F – Powered Platforms, Manlifts, and Vehicle-Mounted Work Platforms

- 1910 Subpart G – Occupational Health and Environmental Control

- 1910 Subpart H – Hazardous Materials

- 1910 Subpart I –Personal Protective Equipment

- 1910 Subpart J – General Environmental Controls

- 1910 Subpart K – Medical and First Aid

- 1910 Subpart L – Fire Protection

- 1910 Subpart N – Materials Handling and Storage

- 1910 Subpart O – Machinery and Machine Guarding

- 1910 Subpart P – Hand and Portable Powered Tools and Other Hand-Held Equipment

- 1910 Subpart S – Electrical

- 1910 Subpart Z – Toxic and Hazardous Substances

You’ll also need to comply with the General Duty Clause, which requires employers to provide a workplace free from recognized hazards that may seriously harm their employees.

We offer a full range of OSHA-compliant training videos that address many of the above standards. These include:

- Electrical Safety Training (29 CFR 1910.301-399)

- Logout Tagout Training (29 CFR 1910.147)

- Hazard Communication Training (29 CFR 1910.1200)

2. Properly Train All Workers

Regardless of how organized your warehouse is, all workers will need proper training to stay safe. Providing the proper training equips your employees with the knowledge and skills to recognize potential hazards, avoid accidents, and handle emergencies. You’ll also be able to avoid the fines that are associated with any serious OSHA violation, which result from failing to provide adequate training on the following:

- Hazardous chemicals

- Fall protection

- Ladder usage

- Powered industrial trucks

- Lockout/tagout procedures

- Electrical wiring

- Emergency response

- Machine guarding

- Personal protective equipment

Because so many standards apply to warehousing operations, you should consider purchasing an annual subscription to our entire training video library that provides a convenient and affordable way to protect workers and stay OSHA compliant. You’ll get unlimited access to training on a wide variety of important topics, including Warehouse Safety Training, Personal Protective Equipment (PPE) Training, and Ladder Safety Training.

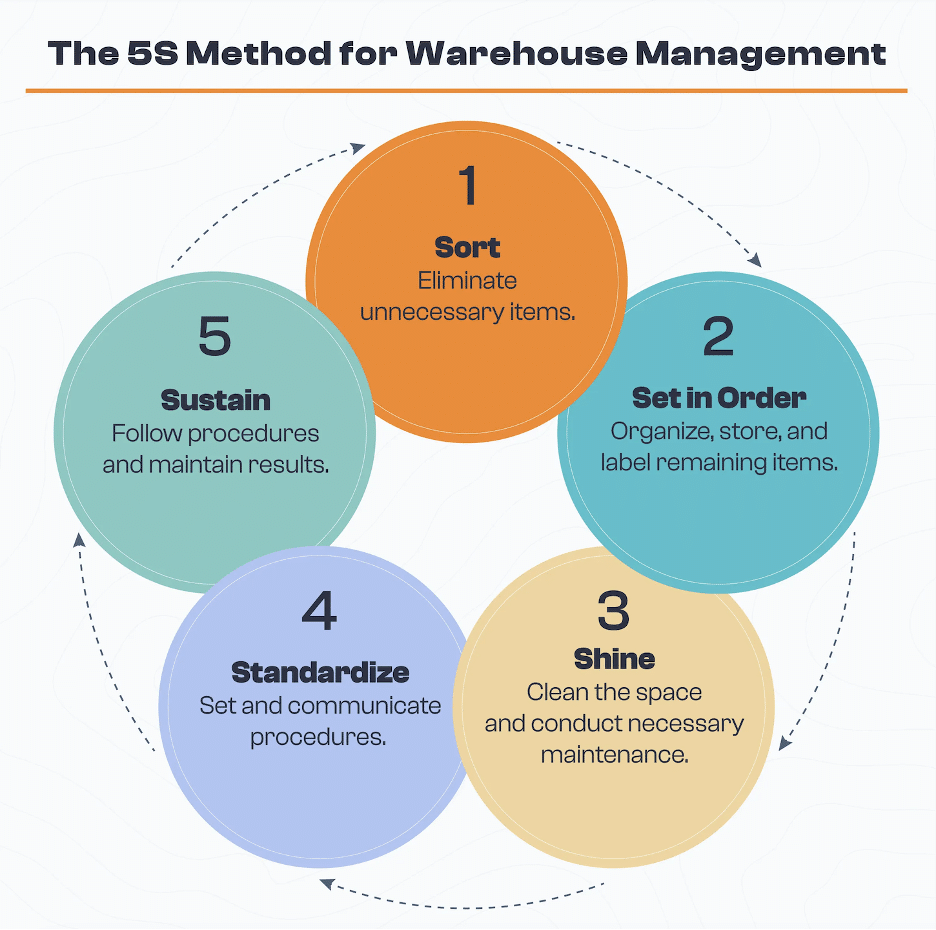

3. Keep Work Areas Clean and Orderly Using the 5S Method

One of the largest contributors to warehouse accidents is disorganized workspaces, like improperly stored materials or cluttered walkways. By keeping work areas and aisles in good repair and free of debris, you can go a long way toward preventing injuries. You keep these areas clean by maintaining a lean inventory, minimizing the number of shipping containers you use to reduce crowding in your facility, and reviewing the 5S method.

The 5S method aims to reduce waste and maximize productivity through organized workspaces.

By using this approach, you can make your warehouses more efficient and safer. For example, implementing the 5S method in your warehouse full of shipping containers can help prevent ergonomic injuries and slips, trips, and falls.

To implement the 5S method you:

- Sort: Sort through items in workplaces and work stations and eliminate anything unnecessary. By “red tagging” rarely used items for relocation or recycling, you can minimize clutter and obstructions, reclaim valuable floor space, and reduce accidents.

- Straighten: Sometimes translated to “Set in order,” this step involves organizing your remaining items. Identify a place for all materials, install compact, ergonomic storage, and limit the number of materials you store.

- Shine: This phase involves cleaning and maintenance. In both a thorough initial cleaning and regular follow-up sessions, workers should sweep and mop floors, clean work surfaces, and maintain machines to prevent leaks and spills.

- Standardize: Once you’ve developed a system, you want workers to be able to replicate it. Standardization benefits from visual management, such as charts, signs, color coding, and pictures for easy reference.

- Sustain: Employers must make a special effort to maintain these new standards over the long term. Implementing regular audits and check-ins, dedicating the proper resources, and fostering a culture of continual improvement can reinforce your message.

Besides minimizing accidents, the 5S system can increase emergency response time, reduce unnecessary consumption, and lower the square footage needed for warehouse operations.

4. Prioritize Safe Operation of Forklifts

Another area within your warehouse that could pose a threat to safety is the improper use of powered industrial trucks or forklifts. To reduce these risks, OSHA requires that all forklift operators be at least 18 years old and complete training and certification under 29 CFR 1910.178(l). We offer forklift safety training that will fulfill the formal instruction component of forklift training.

Operators must be trained on the specific machine they will use and the conditions in which they will operate. This includes training on the following:

- Forklift operations: How to safely use a forklift, including truck controls and instrumentation, motor or engine operation, steering and maneuvering, attachment operation, and vehicle capacity, stability, and visibility

- Equipment maintenance and repair: Proper care of forklifts, including pre-work inspections, vehicle maintenance and repair according to manufacturer recommendations, and the removal of any dangerous machines from service

- Charging stations: Safe battery practices, such as properly positioning forklifts and applying brakes before charging batteries, using proper PPE while servicing batteries, and avoiding open flames, sparks, or smoking in charging areas

- Workplace hazard assessments: Evaluating working conditions for dangers like sloped or slippery surfaces, loading docks and other elevated platforms, electrical wires or equipment, and pedestrian traffic

Additional forklift safety best practices include:

- Enforcing speed limits of 5 mph in warehouse settings

- Slowing down in congested areas

- Using horns at cross aisles or obstructed areas

- Avoiding dangerous behaviors like dock jumping or giving rides to other workers

If you promote a culture of safety around forklift use, you can help prevent collisions, tip-overs, and pedestrian accidents, which are some of the most common and costly warehouse incidents.

5. Promote Ergonomic Practices

OSHA does not have a specific ergonomic standard. However, since musculoskeletal injuries are a leading cause of days off work, you should prioritize safe ergonomic practices that go beyond proper lifting techniques. This includes doing the following:

- Providing training on correct ergonomics in material handling and back safety in industrial environments

- Incorporating ergonomic principles in warehouse design, including proper aisle width and organized storage

- Implementing ergonomic workstations for each specific task to reduce worker strain, including adjustable height platforms, anti-fatigue mats, and proper lighting

- Using ergonomic tools and equipment, like pallet jacks, powered conveyors, and lift-assist devices, to prevent common injuries and improve productivity

- Ensuring employees take regular breaks to prevent fatigue

6. Implement Proper Use of Personal Protective Equipment (PPE)

Most warehouses require the use of PPE like hard hats, safety glasses, visibility vests, insulated boots, protective gloves, and more. By instructing your employees on the correct PPE to use, you can reduce risks from falling objects, debris, chemical exposure, and low-visibility situations. It can also help protect your workers from environmental stressors, like air and noise pollution from trucks and equipment, heat illness in warm warehouses, and cold stress in cold warehouses.

Per OSHA 29 CFR 1910.132, you must assess workplace hazards and provide the appropriate PPE free of charge, along with training on how to use it, proper care, and maintenance. Our PPE training videos include a variety of courses, including eye safety, hearing safety, and respiratory protection.

7. Enforce Lockout/Tagout (LOTO) Procedures

Workers servicing warehouse equipment face serious injury if hazardous energy is not properly controlled. High-risk equipment includes electrical, pneumatic, and hydraulic-powered machines. To increase worker safety, you should consider enforcing lockout or tagout procedures. Some examples of when your employees should implement lockout/tagout include setting up new equipment, repairing circuits, clearing machine jams, and performing routine equipment maintenance. By training your workers on lockout/tagout procedures and reinforcing LOTO safety, you can protect them from potentially fatal accidents.

Per 29 CFR 1910.147, employers must establish an energy-control program that includes the following:

- Energy-control procedures

- Employee training

- Periodic inspections

Your employees who implement lockout/tagout procedures according to the company’s safety plan must receive comprehensive LOTO training to do so. Those who work on equipment or in areas where they might be injured by the release of hazardous energy should receive training only on the purpose and use of LOTO procedures. You should evaluate the procedures at least annually to ensure they meet OSHA requirements and that employees are following them.

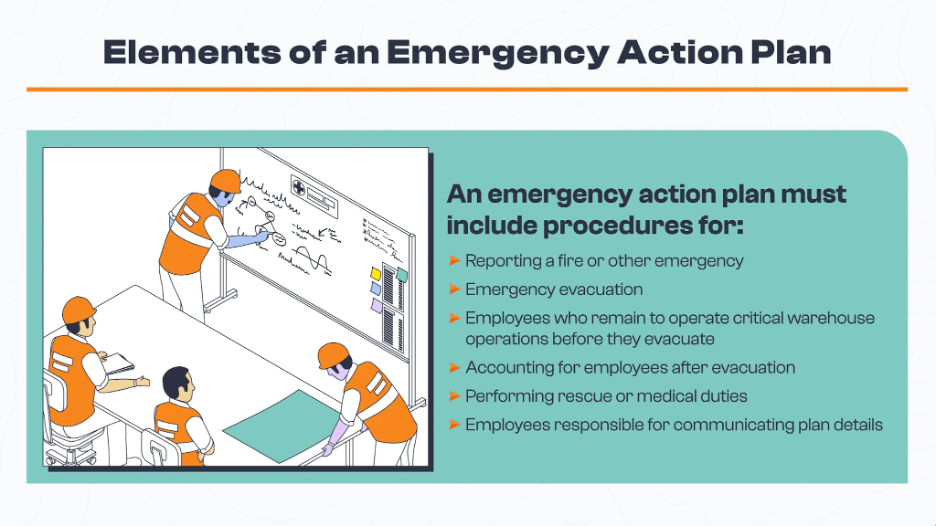

8. Communicate Emergency Action Plans

While following the rest of the best practices on this list can help minimize emergencies, it can’t eliminate them. From tornadoes to fires, natural disasters can cause injuries to workers, loss of company property, and damage to the warehouse environment. By preparing your employees to deal with an emergency before it happens, you can help them respond quickly and effectively when it does.

According to OSHA, warehousing employers should have a plan that describes what workers should do and where they should go in the case of an emergency, including the following:

- Evacuation procedures and emergency exit locations

- Procedures to account for all workers after evacuation

- The location and use of fire extinguishers and other emergency equipment

Once you develop a plan, you must ensure that employees understand what you expect of them in an emergency, including conducting periodic safety drills. Per 29 CFR 1910.38, most employers must keep a written emergency action plan in the workplace for employee review.

However, if you have 10 or fewer employees, you may communicate this plan orally. You must also follow the relevant OSHA emergency planning requirements for exits and exit routes (29 CFR 1910.37), fire hazards (29 CFR 1910.157), medical services and first aid (29 CFR 1910.151), and chemical spills (29 CFR 1910.1200 and 29 CFR 1910.120, where applicable).

9. Conduct Regular Safety Audits and Inspections

Implementing training programs and preparing action plans is not enough, as you must ensure that workers follow the rules and procedures. The best way to support your safety culture is to conduct regular safety audits and inspections. Regular inspections will help you identify potential hazards, ensure employees follow protocols, spot opportunities for retraining, and enhance overall safety in the warehouse.

You can also use OSHA-based checklists during inspections to help focus efforts on the areas that are most likely to pose dangers to workers and to result in costly fines for employers. Below, we have compiled a warehouse safety checklist to help you spot issues before they become major problems.

Warehouse Safety Checklist to Enforce Best Practices

Unfortunately, OSHA does not provide a universal safety checklist that applies to all warehouses, but they do offer a Warehousing Pocket Guide with general recommendations. You can create your own checklist by reviewing the applicable OSHA standards and assessing the hazards at your individual facility. Our download offers you some examples of key hazards and sample questions that you can ask yourself to evaluate your warehouse safety.

What Are the Biggest Warehouse Safety Hazards?

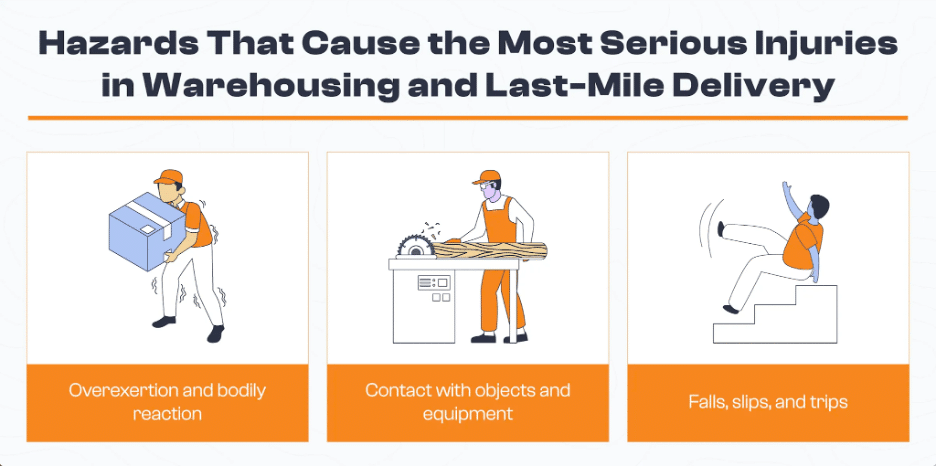

Causes of warehouse injuries can vary from sun damage suffered by dock workers to coworkers colliding in a walkway. However, most injuries can be narrowed down to three major sources, according to the U.S. Government Accountability Office (GAO) analysis of Bureau of Labor Statistics (BLS) data.

Overexertion and Bodily Reaction

Most warehouse accidents that are reported on by news outlets tend to be catastrophic. Surprisingly, the leading cause of worker injury in general warehousing is overexertion/bodily reaction. Overexertion and bodily reaction injuries include the following:

- Non-impact injuries from excessive physical effort, such as lifting, pulling, pushing, and carrying heavy items

- Repetitive motion injuries, such as typing on a keyboard or using screwdrivers

- Injuries from single or prolonged instances of movement like twisting, climbing, reaching, or kneeling

Those employees exposed to this risk will develop musculoskeletal injuries (MSDs) like the following:

- Shoulder and back strain from manually moving materials

- Back disorders from prolonged sitting without lumbar support

- Carpal tunnel syndrome from making repeated movements while handling goods and tools

- Chronic neck pain from looking up at store units and looking backward while driving in reverse

You can help prevent these types of workplace injuries by offering ergonomic training, which we provide in our series of videos on back injury prevention.

Contact with Objects or Equipment

The next biggest contributor to warehouse industry injuries is contact with objects or equipment. This will usually happen when a worker is hit by an object or piece of equipment that is moving or flying. Material handling hazards, including forklift accidents, are a frequent source of this type of injury.

This risk category includes the following examples of warehouse accidents:

- Speeding forklifts colliding with a pedestrian

- Improperly stacked objects falling on an employee

- Materials leaning against a wall, shifting and striking a worker

- Objects dropped into operating machinery, flying through the air, and injuring bystanders

Injuries from objects and equipment can affect any part of the body, but the most frequent locations are the hand, foot, and head. According to the BLS, the most common injuries in this category are the following:

- Cuts and lacerations (29%)

- Bruises and contusions (20%)

- Soreness and pain (12%)

- Bone fractures (9%)

- Sprains, strains, and tears (8%)

If you provide your employees with proper training, you can help prevent contact with objects or equipment. We offer a wide variety of courses to help keep your workers safe, including Forklift Certification, Electric Pallet Jack Safety, and Loading Dock Safety.

Slips, Trips, and Falls

The third-leading cause of injury in the warehousing sector is slipping, tripping, and falling, which accounts for around 17% of fatal work injuries. Some common warehouse slip and trip hazards include the following:

- Stray pallets and carelessly stacked goods

- Broken boards, electrical cords, and other clutter

- Spilled merchandise, including liquids, powders, and loose items

- Wet and icy floors due to weather conditions

- Leaks of motor oil or hydraulic fluid

- Uneven floors or irregular work surfaces

- Poor lighting makes it more difficult to see obstacles

- Unprotected floor holes or wall openings, including chutes

- Elevated work surfaces, such as ladders, forklift platforms, and loading docks

Slips, trips, and falls can result in varying injuries, from minor bruising to fatal head trauma. Here are some of the more common injuries:

- Back pain

- Bruising and bleeding

- Ankle and wrist sprains

- Broken fingers, wrists, legs, or hips

- Dislocated shoulders and torn knee ligaments

- Spinal cord injuries or nerve damage

- Traumatic brain injuries (TBIs)

Our Fall Protection Training and Walking and Working Surfaces videos cover how to recognize and address fall hazards in your workplace, including slippery surfaces, unprotected edges, and elevated platforms. These videos will help educate your employees on the hazards they might encounter in their work environment and how to keep themselves safe.

What Are Other Common Warehouse Safety Risks?

While overexertion, collisions, and falls are the three primary causes of warehouse injuries, some other common safety risks include the following:

- Electrical hazards: Warehouses often have many different electrical systems and equipment. Frayed cords, uncovered junction boxes, and exposed wires are some of the electrical hazards that endanger workers.

- Toxic chemicals: Warehouses that store hazardous chemicals pose risks to employees, including flammable materials, compromised tank systems, and improperly labeled chemicals.

- Improper PPE: Inadequate respiratory protection, improper footwear, and lack of eye and hearing protection increase the chances of injury.

- Stress and fatigue: Fast-paced working environments and continuous performance monitoring systems can increase the risk of worker injury and exacerbate MSDs.

- Extreme temperatures: Employees can suffer temperature stress in refrigerated warehouses, facilities with high heat and humidity, and warehouses without adequate ventilation or climate control.

- Unexpected emergencies: Blocked exits, malfunctioning sprinkler systems, and a lack of training in first aid techniques increase the chance of injuries in an emergency like a fire or chemical spill.

Our comprehensive training kits address many of these common warehouse safety issues, including Heat Stress, Fire Safety Training, and Chemicals and Hazardous Materials.

Keep Your Warehouse Safe with Our Comprehensive Training Programs

Keeping your warehouse safe requires you to use safety training programs to help educate your employees on the dangers in the workplace, as well as how to avoid injuries. To help you address the wide variety of safety hazards and federal regulations that apply to warehouses, we offer over 250 OSHA-compliant safety training videos. If you need just a single safety course to round out your training program, your best option is to purchase one for just $239. If you’d like to have unlimited access to our entire video training library, you can choose an annual subscription and continually access those videos multiple times to use with new employees or subsequent training for current ones.

If you’re interested in using our courses to train your employees, contact us today. We can provide you with more information about our comprehensive safety training courses and help you take the next steps in increasing the safety of your warehouse.