Who Is Responsible for PPE Training? Roles and Responsibilities

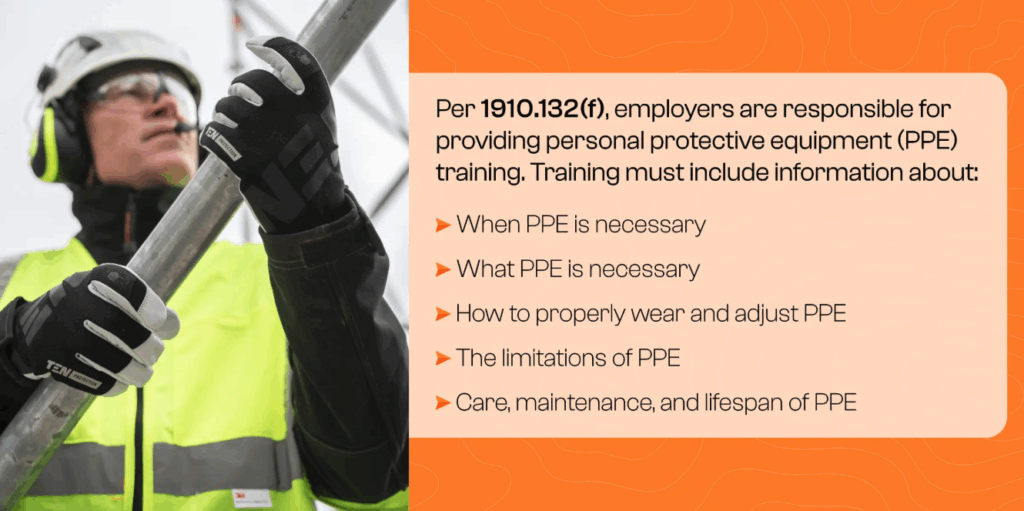

According to the Occupational Safety and Health Administration’s (OSHA) 29 Code of Federal Regulations (CFR) 1910.132, employers must train those employees who are required to use personal protective equipment (PPE). Employees must be instructed on what equipment is required, when it is necessary, how to use it correctly, and how to care for it properly.

Employers must also provide and pay for PPE (with limited exceptions) and ensure it properly fits workers. These regulations are in place to minimize exposure to potential hazards and reduce any workplace injuries and illnesses.

In keeping with federal regulations, employers must also retrain previously trained employees if they have not retained the proper understanding and skills of using PPE. To help employers comply with federal law, we offer a series of PPE training videos that you can use to keep your workers safe and comply with OSHA requirements.

This post delves into PPE training and outlines the requirements for successful completion, as well as offering PPE training materials for employers.

What Does PPE Training Involve?

PPE will vary based on industry. Workplace-specific PPE may include hard hats and goggles for eye and face protection, head protection, leg and foot protection, hand and arm protection, full body protection, hearing protection, respiratory protection, and protection against falls.

Keep in mind that choosing and providing the right equipment means little if your employees don’t wear it regularly or correctly. This is why OSHA requires employers to train each employee on how to use and care for their workplace-specific PPE.

At a minimum, OSHA 1910.132(f)(1) requires employers to train employees who need to use PPE on the following:

- When PPE is necessary

- What kind of PPE is necessary

- How to properly put the PPE on, adjust it, wear it, and remove it

- The limitations of the equipment

- How to properly store, care for, maintain, and dispose of PPE, including understanding the useful life of the equipment

Training requirements also include the following stipulations:

- Conduct the training using a language and vocabulary the employee can understand.

- Ensure each employee demonstrates an understanding of the training.

- Ensure that each worker demonstrates the ability to properly wear and use the PPE before allowing them to perform work requiring the use of the equipment.

- Retrain employees who fail to demonstrate proper understanding or skill level in the use of PPE.

All of our safety training videos are OSHA compliant, helping you satisfy your responsibilities and create a safer workplace.

PPE Roles and Responsibilities

To ensure everyone’s safety, both employers and employees should follow PPE best practices to make sure the job site remains healthy and safe.

Employer Responsibilities

Employers are responsible for the following:

- Training employees in the proper use and care of their PPE

- Conducting hazard assessments to identify and control physical or health-related worksite hazards and determine what PPE is necessary for each task or role

- Selecting the appropriate PPE that is safely designed and constructed, fits workers well, and that is compatible with other PPE

- Providing the required PPE at no cost to the employee, except in limited cases specified in the standard, per 72 Fed. Reg. 64341-64430

- Maintaining PPE, including repairing or replacing worn or damaged equipment

- Periodically reviewing, updating, and evaluating the effectiveness of their PPE program

Employee Responsibilities

In turn, employees must do the following:

- Wear the required PPE correctly.

- Attend the required PPE training sessions.

- Correctly care for, maintain, and clean their PPE.

- Inform their supervisor when PPE needs repair or replacement.

How Long is PPE Training Good For?

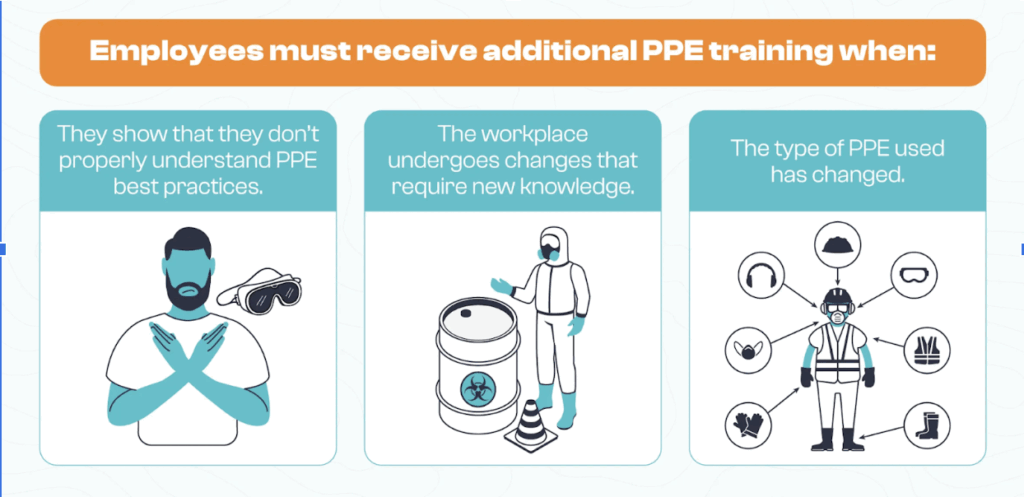

OSHA does not specify a timeframe for follow-up PPE training. Instead, per OSHA 1910.132, employers must retrain previously trained individuals they feel do not have an understanding of the training and the ability to use PPE properly.

According to the standard, situations which require retraining may include — but are not limited to — the following:

- Changes in the working environment that render previous PPE training obsolete

- Changes in the types of PPE needed that render previous training obsolete

- Inadequacies in an employee’s knowledge or use of assigned PPE suggesting they have not retained the required understanding or skill

Other examples include accidents or near-accidents, unsafe behavior, or amended regulations. You may also want to conduct periodic refresher training to encourage continued compliance.

Whether you have purchased individual training videos or an annual subscription, we help make retraining affordable and hassle-free. You can use the relevant PPE training videos as many times as you need.

PPE Training Best Practices

OSHA lays out specific requirements for PPE training, but they do not cover every possible work scenario for your industry. Instead, employers must use government recommendations, industry knowledge, and their own experience to create a robust training program. The following best practices can help you develop a training that’s specific to your industry.

Clear Explanations

The best way to ensure that people will comply with PPE standards is to explain why those requirements are important and how they help protect employees. The best PPE training programs will include the following information:

- Why the specific PPE necessary: Explain what hazards in the workplace threaten their ears, eyes, and head. Then, show how injuries to those parts of the body can be incredibly detrimental.

- How the specific PPE will protect them: Show how using the required equipment properly improves their safety. For example, our Respirator Training Course discusses various types of airborne contaminants and how the right respirator can help protect your employees from harmful chemicals they might breathe in.

- How the training applies to the workplace: Show how PPE can be tailored to your specific work environment. For example, our Construction Worker Eye Safety Training discusses the type of construction tasks that generate debris that can potentially cause eye injuries.

- How to identify signs of wear: Since employees are responsible for notifying employers when PPE needs repair or replacement, you can help them know what to look for, such as scratched or pitted safety lenses or disintegrating masks.

Accurate Documentation

OSHA 1910.132 does not specifically address training documentation requirements. While the OSHA may not require it, it’s still a good idea to document PPE training. By keeping detailed records, you can protect workers, provide evidence of OSHA compliance, and defend yourself against any citations you may face.

Basic documentation includes the following:

- Each employee’s name and signature

- The date of the training

- Types of PPE covered during training

- The name of the training provider

Our safety videos make documentation easier by including trainee sign-in sheets, automated progress tracking, and certificates of completion.

Beyond Training

Creating a robust training program is only the first step. Employers must also consider how to properly assess employees’ knowledge, continue to enforce regulations, and improve the workplace culture of safety.

- Assessment: OSHA 1910.132 requires employees to demonstrate an understanding of the training and the ability to use PPE properly. Our courses include quizzes to help you see how well your employees absorbed the material.

- Enforcement: Employers must also continue to enforce proper PPE usage. This requires employers to check compliance regularly and retrain if needed. If you’ve purchased our workplace safety videos, you can reuse them as much as you’d like.

- Improvement: No safety program is perfect, and even stellar programs need to change with the times and adapt to real-world experiences. Make sure you know how and when to evaluate your training program and prepare to make necessary changes.

Why Purchase Our PPE Training Videos?

If you’re looking to level up your PPE training — or launch a new program — check out our professional PPE training videos.

- All-in-one PPE safety training kits: Our safety training kits include training videos like our full-length PPE Training, Hearing Safety Training, Respirator Training Course, and Construction Worker Eye Safety Training. It also includes presenter’s guides, printable employee sign-in sheets, automated progress tracking, trainee quizzes and answer sheets, and certificates of completion.

- Multiple languages: All videos are available in English and Spanish. This will allow your employees to receive training in the language they’re most comfortable with.

- Variety of formats: You can receive the training through a DVD, USB stick, or online. This allows employees to easily access the course modules they need.

- Affordable prices: Individual courses cost only $239 each and can be used as often as you like. You can also subscribe to our Online Safety Training System for unlimited access to over 250 online safety videos. Those subscriptions cost just $995 for businesses with 1 to 50 employees or $1,495 for businesses with 50 to 100 employees.

If you’re in need of PPE training, you’ve come to the right place to create a safe working environment. With our safety training videos, you can be sure your employees will receive the proper training required by OSHA standards. Contact us today to start building a tailored PPE training program for your workplace.