Arc Flash Incident Response – What You Need To Know

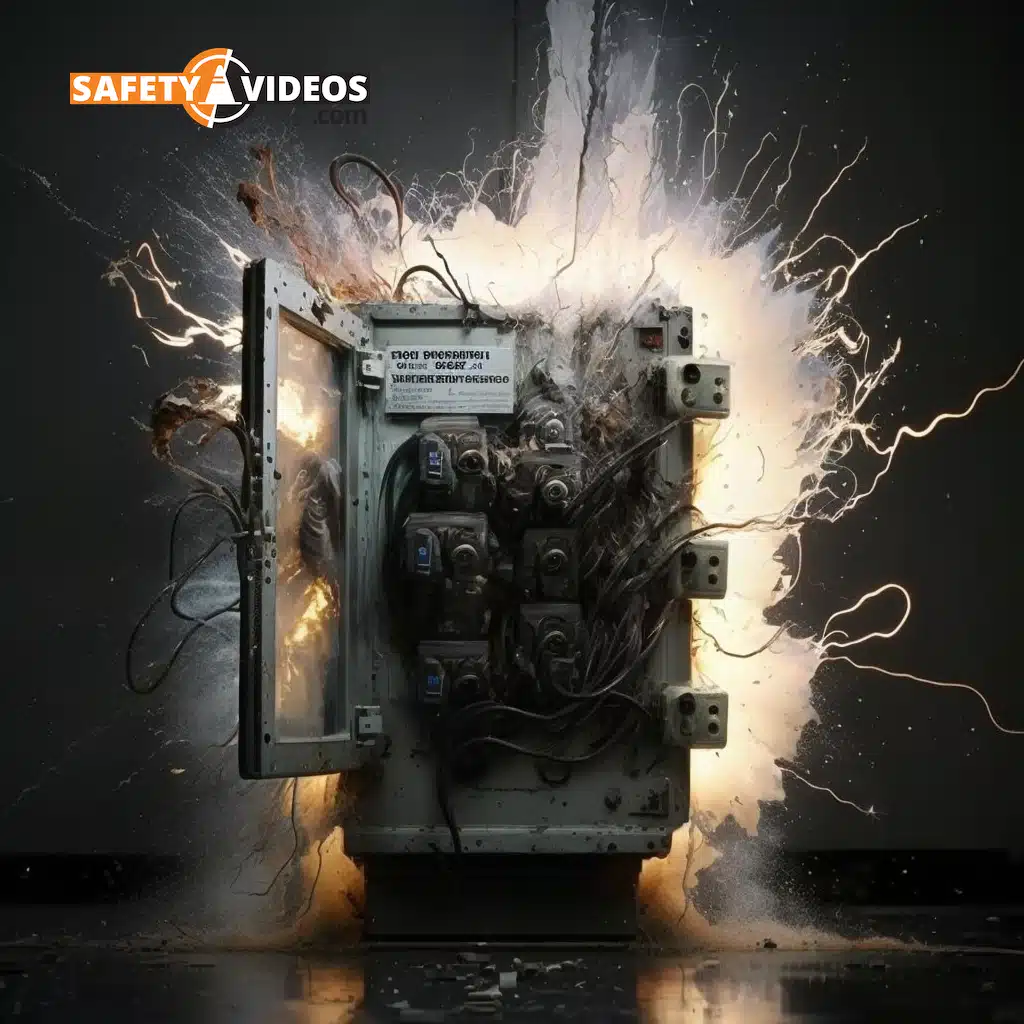

Arc flash is among the worst possible electrical worksite accidents. An electrical current passes through ionized air from an electrical arc in a split second, creating an explosive, often deadly release.

Understanding the risks of working with electricity is integral to identifying hazards and avoiding accidents and is, therefore, key to preventing injuries and casualties from arc flash exposure.

Here’s a basic guide to arc flash incidents, including how and why they occur, recommended prevention and response measures, and the importance of vigilant safety training. We also have a full video-based Arc Flash Training Program as well.

What is Arc Flash?

Arc flash is a dangerous flashover incident involving an electrical current traveling off its intended path to one conductor to reach unintended conductors or the ground.

Experts estimate arc fault incidents occur 5-10 times daily in the US. The results of an arc flash incident can be extremely violent, leading to serious injury or death.

The violent aftermath tends to involve:

- Extreme heat (more than 35,000 °F)

- Sound blast (up to 140 dB)

- Blast pressure wave (more than 2,000 pounds per square ft)

- Flying hazardous objects

- Fire that can quickly spread

Event severity is defined by incident energy and depends on the distance from the arc, the arc duration, and the short circuit current. The three main factors that define the seriousness of arc flash exposure are proximity, temperature, and how long the circuit takes to break.

Common Causes

Essentially a powerful short circuit conducted between two live parts. Several factors can lead to these dangerous incidents, such as worn or loose connections or gaps in insulation.

The following can create an increased likelihood of arc flash occurring:

- Environmental factors, like dust, condensation, corrosion, and temperature

- Equipment issues, including faulty wiring and materials, poor installation, and equipment failure

- Human error, such as dropping tools or the accidental touching of two conductors

The risk of arc flash is increased by large spikes in voltage or voltage transients from lighting or switching reactive loads, which can carry thousands of amps in just a few microseconds.

Arc Flash vs. Arc Blast

Arc flash describes the intense heat and bright light caused by an electrical explosion from a fault.

Arc blast refers to the incredibly forceful wave of sound and pressure that often ensues, occurring instantly in conducive conditions.

How Arc Flash Occurs

What happens during an arc flash incident?

When a power distribution system experiences an electrical fault, a flashover of uncontrolled electrical current deviates from its planned path, instead traveling in the air to reach another conductor or the ground.

The tremendous energy that bursts from the source is converted mainly into light and heat, resulting in the arc flash event. A dynamic pressure wave, an arc blast, and a fierce acoustic wave typically accompany the explosive force.

The sudden discharge creates a sound as loud as a gunshot, heat radiates at temperatures several times hotter than the sun’s surface, and a flash of harmful ultraviolet light is released.

Nothing within a certain distance can be vaporized or melted, including electrical components, creating flaming, molten metal droplets.

Flying molten metal can be launched far at high speeds and lodged in the skin before quickly hardening. The second or third phases can ensue if vaporized metals sustain the arc.

Arc Flash Injury Severity and Hazards

Due to the violent nature of arc flash exposure, injuries sustained in these incidents tend to be serious and permanent and significantly alter victims’ quality of life.

Typical injuries when an arc flash occurs include:

- Severe burns (internal and external)

- Lung damage

- Intoxication from inhaled gases

- Vision loss and eye damage from ultraviolet light

- Hearing loss and ear damage from the sound blast

- Internal injury

- Wounds from flying electrical equipment

- Factors that influence the severity of injuries caused by arc flashes include:

- Proximity to event

- Exposure duration

- Explosion size and temperature

Handling Incidents and Injuries

How do you respond to an arc flash incident?

Cut the power immediately and call 911. Never touch a victim while they are physically still in contact with the electrical source. If electricity can’t be shut off, only attempt to safely separate the victim from the electricity source with a non-conductive object.

CPR should be started if a victim has a pulse but isn’t breathing. If a victim is on fire, douse or smother the flames, but don’t attempt to separate melted clothes from burned skin. Run under cool water (not cold), then cover with a clean, dry cloth. Skin grafts, loss of limbs, and death are not unusual.

Event Aftermath

Arc flash victims frequently suffer scarring and chronic pain and face a variety of social and financial costs, with medical expenses sometimes reaching seven figures.

Employers will be responsible for an array of costs associated with reductions in morale and productivity, along with rehiring and retraining staff in the wake of incidents.

Standard Safety Procedures

Unsafe procedures, faulty materials, and equipment that was not properly installed or poorly maintained can result in disaster in the workplace. Proper training to recognize and address risks is imperative to reduce the risk of incidents and be prepared to respond if one occurs. (You can also check out our complete guide of Arc Flash Safety Tips for more ideas)

NFPA Regulations

What is the OSHA standard for arc flash? The National Fire Protection Association (NFPA) is responsible for defining OSHA-compliant, formal workplace safety regulations for electrical workers. Procedures are frequently updated, so teams must remain current at all times.

The NFPA 70E standard details the compliant regulation for electrical safety in the workplace, addressing requirements for hazard management as they pertain to shock and arc flash incidents.

Personal Protective Equipment PPE

Due to the deadly nature of arc flash intensity, it’s extremely important for employees facing electrical hazards to wear the necessary personal protective equipment (PPE) at all times.

NFPA 70E classifies required arc flash PPE categories into four levels based on the determined arc rating values measured in cal per cm squared.

Appropriate PPE is determined by these categories, which range from 4 cal/cm squared for Category 1 to 40 cal/cm squared for Category 4, with additional equipment required at each level increase.

Arc Flash Boundaries

Especially while work is being performed, boundaries are routinely used to limit the access of various personnel in their proximity to the live part. This is also a good topic to include in your arc flash hazard analysis.

Arc flash hazard intensity is measured by incident energy. A hazard source with an incident energy of 1.2 cal per cm squared, or 5 J per cm squared – or enough to inflict a second-degree burn – requires an arc flash boundary to determine the approach limit.

A Limited Approach Boundary is a distance from an exposed energized electrical conductor that poses a shock hazard risk that someone with adequate protection and supervision may approach.

A Restricted Approach Boundary is a distance from an exposed energized electrical conductor or circuit part that qualified individuals (only) may approach when the electric shock hazard is greater due to inadvertent movement.

Per NFPA 70E, only qualified people are permitted within restricted arc flash boundaries. Qualified individuals are versed in all relevant operations, policies, and procedures and are familiar with necessary components like appropriate PPE, work permits, test equipment, insulated tools, shielding and insulating materials, etc.

Boundary distances are determined based on the current type, the nominal voltage, what equipment is present (fixed and movable conductors and circuit parts, circuit breakers, relays, fuses, etc.), and whether the inadvertent movement can be safely restricted.

The risks are significant within specific approach boundaries for unprotected, unsupervised, and under-qualified individuals. The intensity of pressure and heat involved in arc wave blasts is enough to destroy human tissue and ignite or melt anything in its path.

Working Safely with Electrical Equipment

It’s impossible to eliminate all electrical safety and shock risks entirely, but when employees are prepared with effective training, the inevitable risks can be greatly reduced.

Arc Flash Hazard Management

The importance of protecting workers from arc flash hazards cannot be overstated. Comprehensive, ongoing safety training is necessary for educating personnel so that hazards can be proactively spotted and avoided.

Some recommended prevention measures include:

- Regular inspections are key to discovering hazardous risks, such as corrosion, insulation tears, poor connections, overheated conductors, excess moisture, etc.

- Regular measurement of components

- Routine testing of circuit breakers and relays

- Adhere to national guidelines, including routine part replacement

- Ensure all electrical drawings are current

Only qualified persons familiar with the many factors involved in risk assessment for energized equipment and who fully understand how to employ proper control measures to address potential risks should be allowed to work closely with an electrical system.

When staff members are versed in established hazard management practices, they can more effectively identify issues and risks, reducing the likelihood of a dangerous event. Workplace protocols should be guided by constant awareness and compliance with NFPA 70E.

Keep Employees Safe with Regular Safety Training

Before working in hazardous settings or making any electrical measurements, all employees must undergo comprehensive electrical safety risk training and gain a full understanding of their employer’s standards and procedures.

Effective training is vital to educate workers about the dangers of working with electricity, such as electric shock and arc flash. Teams consistently taking the appropriate precautionary steps every day and knowing which actions to take if an incident occurs are at the core of protecting electrical workers and keeping job sites safe.

Final Thoughts

When employees handling electrical hazards are thoroughly trained to reduce the risk of accidents, safe workplace practices become the standard, and devastating outcomes are successfully avoided. Knowing your Arc Flash Incident Response Plan in advance can only help you and your employees.