Scissor Lift Training – [Complete Safety Certification Video Kit]

$239

Using scissor lifts can make jobs easier and more efficient, allowing you to save time and money. However, scissor lifts can also be dangerous, especially when employees use them unsafely. This Scissor Lift Certification Training is designed to show employees how to use this important machine properly, safely, and without incident.

What is Covered in This Scissor Lift Certification Training:

The Scissor Lift Training includes safe handling, maneuvering, and wearing appropriate body harnesses and other personal safety equipment while operating a scissor lift. The training will teach scissor lift operators several key fundamental items:

- What hazards are associated with using a scissor lift, and what lift training is required by OSHA? (Scissor lift hazards include tip-overs, falling objects, overhead hazards, and fall protection)

- What are the “safety best practices” to be aware of as a scissor lift operator, and what are the key concepts that need to be a part of any scissor lift training program?

- What are the OSHA regulations and requirements to ensure your operators are authorized and properly trained on the scissor lift?

- What are the most common types of scissor lifts? (Electric, diesel, propane, and gas-powered)

Scissor Lifts and Safety Training Topics:

- Where are scissor lifts most commonly used? (They can be used indoors on finished floors or other lifts are meant to be used outdoors in rough terrain)

- How often and when should you inspect the scissor lift?

- How long is a scissor lift certification good for?

- The concept of fall protection as it relates to scissor lift training (If you want more in-depth training on fall protection we have that as well)

- Why is it important for the operator to review the scissor lift safety manual?

- How and when do employees need to be retrained and re-authorized as part of any scissor lift certification training program? (Retraining will be required if the scissor lift operator has an accident, workplace conditions change and present a new hazard, you need to learn a new type of scissor lift than the one you were previously certified on, or you are observed operating the lift in an unsafe manner)

Scissor Lift – Additional Discussion Points In This Course:

- How to identify and avoid overhead hazards (A key part of any scissor lifts safety procedures and training)

- What is ANSI, and what do they have to do with scissor lifts? (ANSI is the American National Standards Institute, and in 2020, they made revisions to the Standards for mobile work platforms)

- Is an Aerial Work Platform or AWP the same or different from a Mobile Elevating Work Platform or MEWP?

- What is the ANSI “Job Site Safety” requirement for scissor lifts? (Requires a “Safe Use Program” when scissor lifts are used, Doing a “Risk Assessment” for each job that a scissor lift performs, and strutting a “Rescue Plan” for each type of lift used on the job site)

- What design standards did ANSI change in regard to scissor lifts? (First, all new lifts must have a “gated entrance”, they have disallowed the use of chains for entrance guards, and the minimum height for platforms was raised from 39 inches to 43 1/2 inches)

- Since ANSI updated their Standard, what new alarms and safety devices are required? (A “Safety Load Limit” alarm is now required, as well as a sensor that will stop the lift if the limit is exceeded, and a “Wind Speed Sensor” for any scissor lift used outdoors)

- Do old scissor lifts need to be retrofitted to the new equipment, alarms, and sensors required by ANSI? (No, only newly produced machines are required to have these installed)

ANSI Requirements for Mobile Elevating Work Platforms or MEWP’s:

- Does ANSI require both operators and occupants to be trained on scissor lifts? (Yes, both an operator and an occupant need to be trained on proper operation and safety topics before using the lift)

- How do employers conduct the required Risk Assessment prior to using lifts? (This is a fairly simple process of identifying potential hazards and developing control measures and safe working procedures to address those hazards that were identified)

- Does ANSI require that all required “Rescue Plans” be written, or can they be delivered to workers verbally? (ANSI requires that your Rescue Plan be written and included in your Company’s employee training manual)

- What must scissor lift operator training include? (required training includes the hazards of using a scissor lift, the safe work practices that must be followed, how to recognize and avoid unsafe conditions, how to perform a safety inspection on the lift, and how to handle emergencies)

- When is the Retraining of scissor lift operators required? (If new hazards are identified on the job site when you are exposed to a new type of lift that you haven’t previously been trained on, and finally, if you have had an accident or have been observed using the lift in an unsafe manner)

This Scissor Lift Course Also Discusses Machine Differences, Pre-Shift Inspections, and More:

- How are aerial and scissor lifts different? Can an aerial lift operator use the same certification? (Aerial lifts are a completely different machine, and we have specific training for that machine)

- Why is scissor lift certification training so important, and what are the OSHA regulations that require an operator to be certified? (Because they are dangerous machines that cause an average of eight fatalities each year)

- What are the two inspections that are required before using the lift (the pre-start and worksite inspection)

- How to set up work zone warnings like signs, tape, cones, or other items to restrict access and let others know you are working in the area

- When would the operator be required to wear a personal fall restraint or fall arrest device?

- What are the different types of personal protective equipment or PPE that is available and recommended for scissor lift operators

- How to properly store and place the lift out of service when not in use

- and much more…

If your employees use scissor lifts, you need this training program. This scissor lift safety procedures training video will teach your operators the ins and outs of safety on this powerful machine.

Scissor Lift Training Delivery Methods:

This training is offered on DVD or USB Stick and is available in English or Spanish. We also offer this training in an online course, either as a standalone program or as part of our larger online safety training library. This training course is 22 minutes long.

This training video focuses on the OSHA Training Requirements for Scissor Lifts.

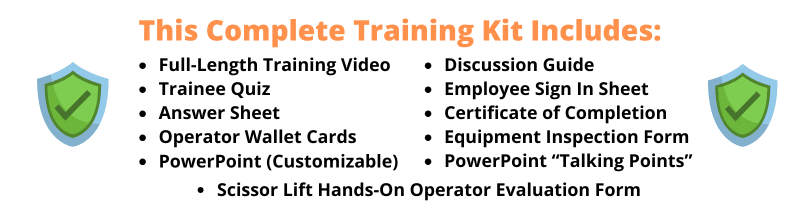

This Complete Scissor Lift Training Program Includes These Items:

- Full-length Scissor Lift Safety Certification video

- Employee quiz and answer sheet

- A “Presenter’s Guide” if you are going to do the training in person

- A Printable Certificate of Completion. You can print as many copies of the certificate as you need

- Customizable Powerpoint and Separate “Talking Points” Document

- Printable scissor lift operator wallet cards to indicate your operators are certified

- A Scissor Lift inspection form that you can reprint and reuse as many times as you need

- A printable training sign-in sheet to keep track of your training program

- Printable “Practical Assessment” Form for the “Hands-on” Evaluation of the operator’s skill in operating the lift.

Scissor Lift Training Video – Full Length Preview:

22 reviews for Scissor Lift Training – [Complete Safety Certification Video Kit]

| 5 star | 72% | |

| 4 star | 22% | |

| 3 star | 4% | |

| 2 star | 0% | |

| 1 star | 0% |

![Scissor Lift Training - [Complete Safety Certification Video Kit]](https://www.safetyvideos.com/wp-content/uploads/2022/02/products-1021G-2-150x150.png)

The memory stick wouldn’t play the whole video.

You guys made it right and sent me a link.

Thank you

Good information, easy to follow