HAZWOPER Electrical Safety Training – [Complete Video Kit]

$239

When dealing with a HAZWOPER emergency or hazardous materials situation, you need to consider electrical dangers. This HAZWOPER Electrical Safety Training in HAZMAT Environments video will teach your employees what they need to know when electricity meets hazardous materials. Whether dealing with arc flashes, high temperatures, sparking panels, or other electrical issues, it can turn your HAZWOPER issue into a nightmare situation. By teaching your employees how to deal with these electrical considerations through engineering controls and other safe work practices, everyone will be safer.

This HAZWOPER Electrical Safety in HAZMAT Environments Training Will Cover the Following:

- What are some of the effects of uncontrolled energy? Three examples include:

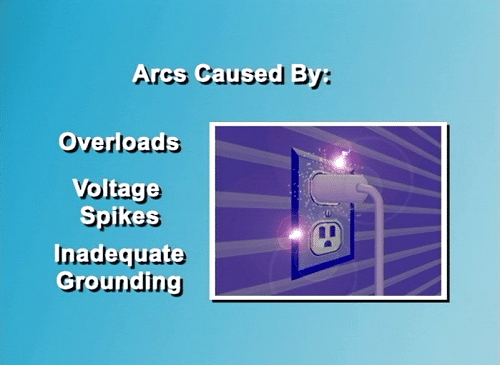

- Arcs – This is the electrical discharge crossing a gap between two points and can occur between two circuits that are improperly grounded, overloaded, or have voltage spikes

- Sparks – these are incandescent particles that can emit visible light when being heated

- High temperatures – This might be the result of worn insulation or high voltage, which causes the line to heat up

- What are the three classes of HAZMAT area locations under the National Electrical Code (NEC):

- Class 1 Area: Electricity could ignite airborne flammable vapors or gases. Examples of these areas might include hospitals, chemical manufacturers, dry cleaning plants, spray finishing areas, and refineries.

- Class 2 Area: This is where airborne combustible dust is present such as in flour and feed mills, carbon processing plants, and grain elevators.

- Class 3 Area: This is where ignitable materials are present, but they are not airborne. Examples of these areas include flax seed processing plants, locations that produce sawdust, textile mills, and cotton gins.

- How are engineering controls put in place to prevent electrical mishaps?

- What are class 1 intrinsically safe systems, and why are they important?

This HAZWOPER Electrical Safety Training Video Also Discusses:

- What are some drawbacks of intrinsically safe systems? (Examples include a system that is only safe in one HAZMAT environment and it might be unsuitable for another environment, there is no intrinsically safe system for use in all environments due to the broad range of chemicals used in various industries, and finally, different hazardous materials have different flashpoints)

- Other engineering controls include hermetic seals made of plastic or metal, oil immersion which uses a layer of oil which acts as a fire barrier, or encapsulating seals made of epoxy, wax or tar)

- What are the two most common work practices in a Class 1 environment?:

- Purging – Uses non-flammable gas called purgatives to flush flammable atmospheres from enclosed or confined spaces

- Inerting – Uses non-flammable gas to displace oxygen

- What are some commonly used purgatives? (except in Class 2 environments):

- Nitrogen

- Carbon dioxide

- Positive pressure air

- What are some common problems with purging or inerting?

- What precautions need to be taken before someone can enter an inerted space? (it must be tested to see if it can support life)

- Whare are some items an entrant must wear when entering an inerted space? (An OSHA-approved supplied-air respirator (SAR), a lifeline, and a harness)

- and much more…

Training your staff on how to deal with electrical issues in a HAZWOPER/HAZMAT environment is critical to their safety and to the welfare of your business. This HAZWOPER training on electrical safety is a key part of any training program. The training video is 24 minutes in length, and comes in either an English or Spanish-speaking DVD or USB stick.

HAZWOPER Electrical Safety Training Video – Full Length Preview:

![HAZWOPER Electrical Safety Training - [Complete Video Kit]](https://www.safetyvideos.com/wp-content/uploads/2022/09/HAZWOPER-Electrical-Training2-150x150.png)

Reviews

There are no reviews yet