HAZWOPER PPE & Decontamination Training

$239

Your HAZWOPER team needs to understand how to decontaminate their Personal Protective Equipment after each use. Doing this helps prevent potential illness or injury. That’s why this HAZWOPER PPE Decontamination Training is so important. It will educate your employees and get them the information they need in order to properly decontaminate their PPE.

This HAZWOPER PPE Decontamination Training Covers:

- What types of PPE are used in a HAZWOPER work area? (Face shields, boots, respirators, CPC or chemical protective clothing, hard hats, etc.)

- What types of situations or hazards does PPE protect your employees from? (falling objects, gases, vapors, and more)

- How is PPE decontamination defined, and what does it entail?

- How do work practices and engineering controls help keep workers safe in a hazmat work environment?

- What are the four levels of HAZMAT PPE, how do they differ, and what are each used for? (Levels A, B, C, and D)

- Which category of Personal Protective Equipment protects the worker from “immediate dangers to your life or health?”

- What role does heat stress play in an employee’s PPE use?

- What are the signs of heat stress, and how can they be reduced in a situation where PPE is required?

- What does OSHA say about contaminated PPE? (OSHA states that nothing can leave a hazmat site without being decontaminated)

- How is decontamination defined, and how does it work?

- What is a “contamination reduction corridor” or CRC? (the CRC keeps the decontamination process confined to a limited area while being decontaminated – this keeps the contamination from spreading)

- What are the different stations in a CRC?

- What types of decontamination equipment is used in a contamination reduction corridor? (Things like hose sprayers, towels, washtubs, soft-bristled scrub brushes, drums, wash bins, and more)

- What types of cleaning solutions are used to decontaminate PPE? (Usually, simple detergent mixed with water)

- How should decontamination cleaning solutions be disposed of under OSHA after the process is complete?

- What does a typical CRC line look like, and how does it work?

- Usually, the first station is a drop-off spot for all of your tools that will need to be decontaminated

- Next, you will step into a small pool where the outer suit wash occurs. You are sprayed with a cleansing solution (usually soap and water) from head to toe. Further, you will be scrubbed with a decontamination solution

- You will then be rinsed, and your suit and respirator/SCBA will be removed

- You will then wash your hands and face or take a more thorough full body wash

- At this point, you will go through medical surveillance

- After your medical exam, you will have completed the contamination reduction corridor process

- and much more…

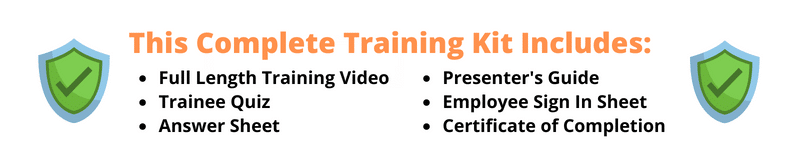

Training your employees about HAZWOPER PPE Decontamination is an important part of any HAZWOPER training program. Your employees must understand how to use their Personal Protective Equipment and, more importantly, how to decontaminate it after work ends. This training is available on a USB stick or on a DVD and comes in either English or Spanish-language versions.