What Is a Fall Protection System?

Fall arrest equipment and other PPE are lifesavers for overhead workers because they can protect you by stopping or preventing you from dropping, like hitting the brakes on a roller coaster ride. This gear kicks into action after a worker slips and grabs hold of them, stopping their decline while still hanging in mid-air.

On the other hand, fall restraint equipment is like a trusty companion with a different mission. It’s all about prevention in the first place, acting like a guardian angel there to enforce safety.

So what is a fall protection system? It’s a combination of all these items coming together to keep workers safe.

This article delves into the types of fall prevention systems and closely examines what OSHA and the American National Standards Institute (ANSI) say about them. If you’d like to check out a video-based Fall Protection Training program, we also have that.

What Is the Meaning of Fall Protection?

This type of protection involves equipment and systems that prevent falls or minimize their impact.

A competent person must identify fall protection system risks, components, and equipment. They have the authority to address any identified hazards and safety issues promptly. If you want to provide your employees with additional training, we have a Fall Protection Toolbox Talk that you can share with your team.

What Are the Fall Protection Systems?

There are different levels of protection systems:

- Prevention: A guard rail system acts as a barrier to prevent accidents.

- Decline Travel Restraint: Fall restraint limits a worker’s movement.

- Last Resort: Fall arrest involves using equipment to safeguard workers in case of an unexpected dropping.

1. Prevention—Passive Fall Protection Systems

Passive fall protection systems are convenient to install and maintain. It’s always preferable to employ prevention methods rather than dealing with the consequences of accidents.

Also, passive fall protection systems like guardrails and safety netting offer protection without requiring specific training. But, remember, according to OSHA regulations (1910.29 (b)), guardrail systems should have a self-closing gate with a top rail, mid-rail, or equivalent intermediate member.

Active Fall Protection Systems

Both fall arrest and fall restraint systems are active fall protection systems. However, according to the OSHA update to 1910 Subpart D, it’s now called “travel restraint” because the system restrains workers’ travel, not the risk of falls.

So, what does a travel restraint system entail?

2. Travel Restraint Systems

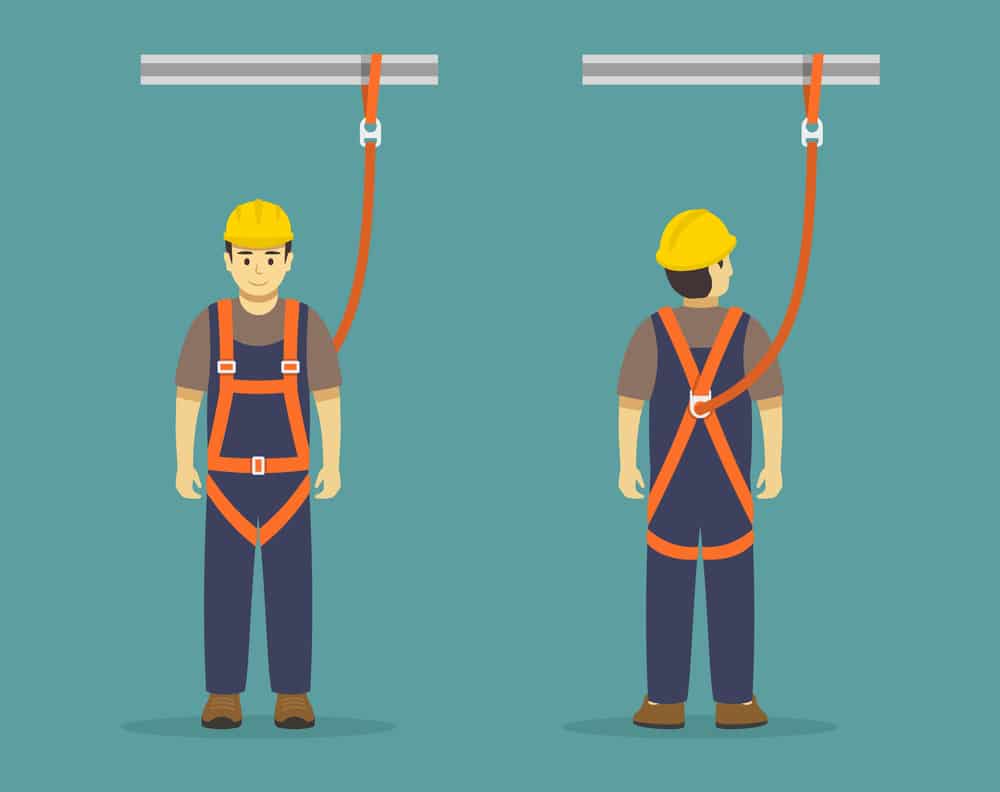

In restraint equipment, the lanyard is a key component. It’s a short, lax line, either rope, wire, or web strapping, with connectors at both ends. The ends attach to a full-body harness and a deceleration mechanism, shock absorber, anchorage connector, or anchor points.

The rope in a travel restraint system carries forces from a body support (such as a harness) to an anchorage or connector. Inspect any lanyard for signs of damage, including:

- Fraying

- Cuts

- Burns

- Knots

Check off the following:

- Is the inner core intact?

- Is the rope clean?

- Is it free of impurities (paint or rust staining)?

Positioning Systems

Work positioning equipment falls under the fall prevention and restraint category but differs from a fall restraint system. A work positioning system specifically supports and suspends a worker from a vertical surface at an elevated height.

The worker connects the lanyard to their body harness and a secure anchor point. It keeps them in a working position, hands-free. However, it’s vital to have additional protection, like a fall arrest system, for extra security.

3. Personal Fall Arrest System (PFAS):

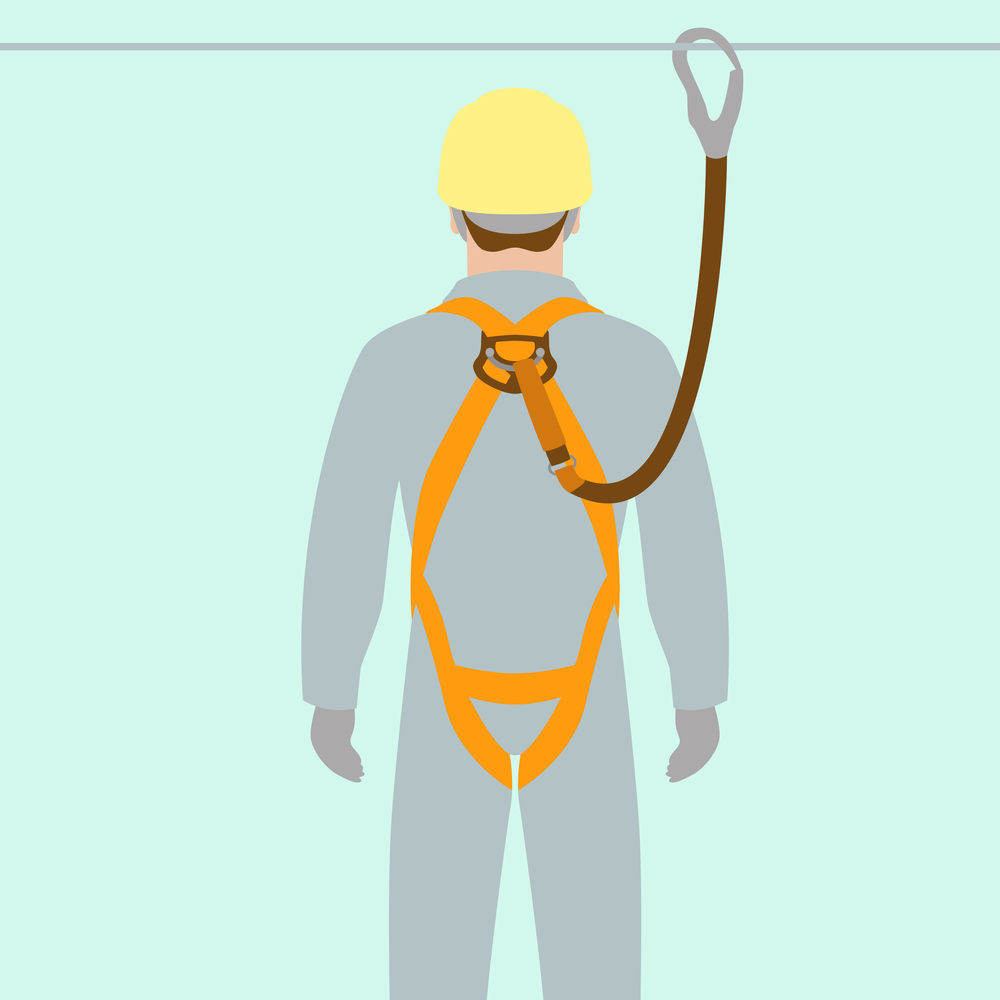

A Personal fall arrest system stops workers from plunging when working at heights during an accident. It includes equipment like anchorage points, connectors, body harnesses, or belts and may also have additional components like a lanyard, lifeline, or deceleration device, which are combinable.

Personal fall arrest systems must prevent a worker from falling more than 6 feet and coming into contact with a lower level. They include a full-body harness, connecting devices, and a secure anchorage design. In addition, workers may utilize a D Ring—an attachment point on body belts and harnesses for other fall prevention and positioning design components.

In terms of safety, a deceleration device is a mechanism that absorbs energy during a drop. Factors that contribute are deceleration distance—the extra distance a falling person travels before stopping when the apparatus kicks in, excluding lifeline stretching and drop distance.

A lifeline consists of a flexible line. It connects to an anchorage at one end for vertical use or anchorages at both ends for horizontal use (vertical & horizontal lifeline), serving as a connection point for other components. Self-retracting lifelines and lanyards permitting more than a 2-foot decline should be able to handle at least 5,000 pounds of force.

Inspection

It’s crucial to inspect any fall arrest system, including the lanyard and self-retracting lifeline, regularly for safety. When examining the fall arrest system and lifeline rope, check for the following:

- Heat damage

- Kinks

- Missing or damaged thimbles

- Loose terminations

- Corrosion

- Wire rope distortion (e.g., birdcage)

- Broken wires

- Separation of strands

- Abraded wire

Swing Fall Hazards

When the anchor point in a personal fall arrest system is not always directly above the worker’s head, falls can occur in a horizontal direction. The angle between the anchor and the worker determines the arc of the downfall.

What Is the OSHA Standard for Fall Protection Systems?

OSHA acknowledges these are complex incidents, and the safety factor involves many elements. The occupational safety standard addresses both human and equipment-related aspects of safety.

Although not explicitly mentioned, OSHA accepts a fall restraint system as an alternative to fall arrest systems if the restraint system prevents access to the hazard.

OSHA recommends that fall restraint systems withstand at least 3000 pounds or twice the maximum arresting force needed to avoid exposure to potential fall hazards—when determining, consider site-specific factors such as walking or leaning.

PPE in the US

PPE is crucial for your safety, but these safety components must meet specific standards and requirements. Consider the following requirements:

- The connectors should resist corrosion, have smooth surfaces, and avoid damaging other parts.

- Lanyards and vertical lifelines need a minimum breaking strength of 5,000 pounds to handle heavy loads.

- For a self-retracting lifeline or lanyard with a maximum free fall distance of 2 feet, its components should withstand at least 3000 pounds when fully extended.

- D-rings, snap-hooks, and carabiners must withstand a minimum tensile load of 5000 pounds without damage.

- The connectors should also undergo a proof test with a load of 3600 pounds without any permanent defects. The gate strength of snap-hooks and carabiners should withstand a minimum load of 3600 pounds without separating by more than one-eighth of an inch.

- The snap-hooks and carabiners should be of the automatic locking type, requiring consecutive movements to open them.

Fall Arrest Systems

- When dropping, the force exerted on your body should not exceed 1800 pounds to protect your body from excessive impact.

- Fall arrest systems should stop you completely and limit how far you travel after dropping to 3.5 feet to prevent you from falling too far and potentially injuring yourself.

- The equipment must be strong enough to handle twice the potential impact energy of a free fall from 6 feet or whatever distance the system allows, thus ensuring the system can withstand the forces generated.

- Ensure the equipment never comes into contact with your neck and chin area to prevent potential harm to your sensitive areas.

Wrap Up

It’s important to remember not to connect snap-hooks and carabiners directly to particular objects like webbing, rope, or each other. It could accidentally cause them to disconnect, putting you at risk.

These safety requirements are in place to ensure fall protection equipment is reliable and effective, providing workers with the security they need when working at elevated heights. Remember to prioritize safety; work safe!