Fall Protection Toolbox Talk – [Quick & Easy for 2023]

Falls are a leading cause of serious injuries in the workplace and can even lead to death in certain circumstances. Therefore, fall protection is a critical part of occupational safety for every industry. From construction sites to offices, each and every workplace should prioritize preventing falls and training employees how to protect themselves against fall hazards. We also have a video based Fall Protection Training Certification course that you should check out as well.

In the toolbox talks on protections against injuries from falling, you’ll learn what safety procedures must be followed and recommendations you can use to ensure your wellbeing on any worksite. Use this comprehensive fall protection toolbox talk to review everything related to falling and preventing falls in the workplace. Finally, make sure you and your employees understand the requirements involved with a fall protection program.

What Are the Main Causes of Falls in the Workplace?

While falls are a risk in every type of work environment, the factors that can contribute to fall hazards vary widely. When falls occur, the factors responsible can usually be divided into one of two categories: unsafe conditions and unsafe actions.

Unsafe Conditions

Unsafe conditions can be thought of as obstructions, slipping hazards, and other dangers present in the work area that can lead to workers falling.

Some examples of unsafe conditions are:

- Cluttered, slippery, or unstable walking and working surfaces

- Unprotected edges of buildings or scaffolding

- Holes in the floor or walls

- Unmarked elevation changes

- Improperly worn fall protection equipment

- Ladders leaning in an unsafe way

- Damaged equipment

Unsafe Actions

Unsafe actions are hazardous decisions or avoidable errors made by employees.

Potential unsafe actions that can result in a fall include:

- Improper use of ladders and step ladders

- Leaning over guardrails

- Working high up with no safety equipment or fall prevention equipment

- Ignoring recommended safety advice

Types of Fall Protection Equipment

If working at heights is unavoidable, using equipment that is specifically designed for fall protection can do a lot to mitigate the risk of injuries. Safety features can also be utilized in the workplace to lower the chance of free fall. The following are all parts of a fall protection system:

Guardrails and Hand Rails

Guardrails and handrails are important safety measures and should be in place anywhere workers might fall. For instance, stairways are an extremely common place to fall. All stairs should have handrails people can hold onto for their safety to prevent falls from tripping or moving too quickly on the steps.

Note that employees should walk slowly while moving up and down the stairs. Never run or jump in a stairwell.

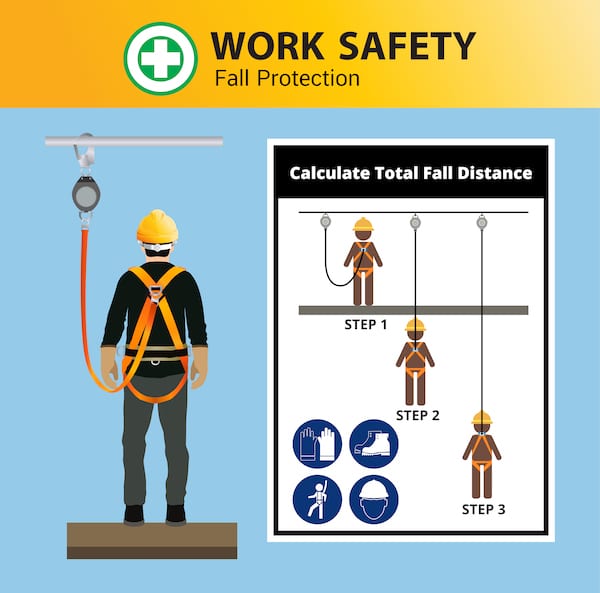

Personal Fall Arrest Systems

In some cases, a personal fall arrest system may be necessary to catch workers if they fall and prevent them from suffering serious injuries. A fall arrest system usually consists of a full-body harness with a self-retracting lanyard and a deceleration device that is attached to an approved anchor point. The type of full-body harness that is appropriate for a given task depends on the work being done.

When setting up a fall arrest system, make sure to take into account the weight of the tools the worker will be using as well as the weight of the worker. Bear in mind that the harness must be worn properly in order to function. An improperly utilized fall arrest system could fail, resulting in an unprotected fall that could lead to serious injury or death.

Best Practices for Fall Protection

Regardless of the type of workplace, all employees should be aware of potential fall hazards and basic practices for fall protection. Every good safety system must include education about different methods of fall prevention, including ladder safety and how to spot and correct a potential fall hazard.

1. Keep Walkways Clear

Every walking surface at the job site should be cleaned frequently and kept free of clutter. Obstructions in the walkway constitute a tripping hazard.

2. Wear Proper Footwear

Shoes on a job site should be slip-resistant, with proper traction and a good grip. Open-toed shoes should never be worn in a factory or at a construction site.

3. Keep Cords Tidy

Extension cords, chargers, power cords, and other types of cordage are easy to trip over. Keep all cords in the workplace under control and tucked out of the way whenever possible.

4. Maintain Good Lighting

Falls are more likely to occur when visibility is poor. Make sure the work area is well-lit at all times.

5. Use Signage

Signs should be implemented at sites where the risk of a fall is greater. Search the job area for gaps, holes, uneven ground, and unexpected steps, and make sure each of these potential hazards is labeled with a warning sign.

Signs should also be utilized when the floor is wet to prevent people from slipping.

6. Use Caution on Ladders

Climbing up a ladder is an extremely common fall hazard. Great care should be taken when using ladders, especially extension ladders as they tend to be longer and less stable.

Before climbing a ladder, check to make sure it’s stable and positioned on level ground, and ask another worker to stand on the lower level and hold the base steady while you’re up there. Take down the ladder when it’s not being used so it won’t fall on anyone.

Never jump onto or off of a ladder, and make sure your hands are free to keep three points of contact on the ladder at all times. Don’t tie or splice two ladders together to make a longer one. Avoid using a ladder if the wind is strong, and never climb higher than the third rung from the top.

7. Check Floors

As you move around the job site, keep an eye out for cracks or holes on the ground that could catch people’s toes and cause them to fall. Alert a supervisor to fix any problems you encounter, and make sure to post signage to alert other people to the danger.

8. Perform Regular Risk Assessments

For the health and safety of everyone at the job area, regular assessments should be carried out to check for potential hazards. Search for any unsafe conditions around the job site, including improperly stored ladders, holes in the walkways or walls, and obstructions that could be tripping hazards. Conduct thorough checks of each fall arrest system and harness before use to make sure everything is functioning properly.

In addition to the risk assessment checklist, make sure to design a rescue plan to be executed if a fall occurs.

Fall Prevention is the Key to Fall Protection — Toolbox Talk Conclusion

Keeping workers safe from falls means educating them on fall hazards and teaching them how to spot potential hazards. Create a fall rescue plan for your workplace, and make sure all employees know how to avoid falls and use a ladder safely. If your job site requires the use of a fall arrest system, make sure the harness fits and that the system can bear the appropriate amount of weight.

Ultimately, most falls are caused by lack of attention or carelessness. Don’t underestimate the importance of fall protection in the workplace. Refer back to this fall protection toolbox talk to ensure you’re prepared.