Housekeeping Best Practices in the Warehouse

To an outsider, housekeeping may not seem like a major concern within a warehouse. But warehouse managers know it’s vital to running a well-maintained operation.

While accidents can occur at any time, keeping the warehouse free of hazards can help protect your staff. It can also improve morale and productivity.

Read on to learn how housekeeping is important to warehouse management and how your workplace can benefit from more good housekeeping practices. If you want to take your learning to the next level, check out our Warehouse Safety Training Course for all warehouse workers.

What Is Warehouse Housekeeping?

Warehouse housekeeping refers to the tasks involved in cleaning and organizing your warehouse. Like other kinds of housekeeping, it can include dusting, sweeping, and other tasks to keep things tidy.

Unlike other kinds of housekeeping, it also includes keeping aisles clear, thinking about fire prevention, and preventing other hazards. It’s about keeping things tidy, yes. But its most important task is keeping your employees safe.

Why Is Warehouse Housekeeping So Important?

Here are four compelling reasons to prioritize keeping your warehouse clean and free from obstructions.

1. Effective Housekeeping Keeps People Safe

Trips, slips, falls, and falling objects are the main hazards in a warehouse. Trip hazards include crowded aisles, boxes or other materials on the floor, and cords or wires – all things that can be minimized with proper organization and cleaning.

Slips are often caused by spills of water or grease on the floor. Regular cleaning can keep workers safe.

Storage areas should be well-maintained to prevent loose objects from falling.

2. Housekeeping Is Part of Safety Culture

If your facility isn’t clean, it isn’t safe. Instituting effective housekeeping standards and keeping things clean will help reinforce other messages your company sends about safety.

3. Poor Housekeeping Decreases Efficiency

Proper cleaning and maintenance make your warehouse run better. Forklifts and employees can move unimpeded when aisles are clear of clutter.

4. Effective Housekeeping Saves Money

In 2021, the total cost of workplace injuries was $167 billion. And that doesn’t account for the non-injury costs resulting from a messy warehouse – loss of productivity and low morale from having a cluttered workspace and damaged equipment.

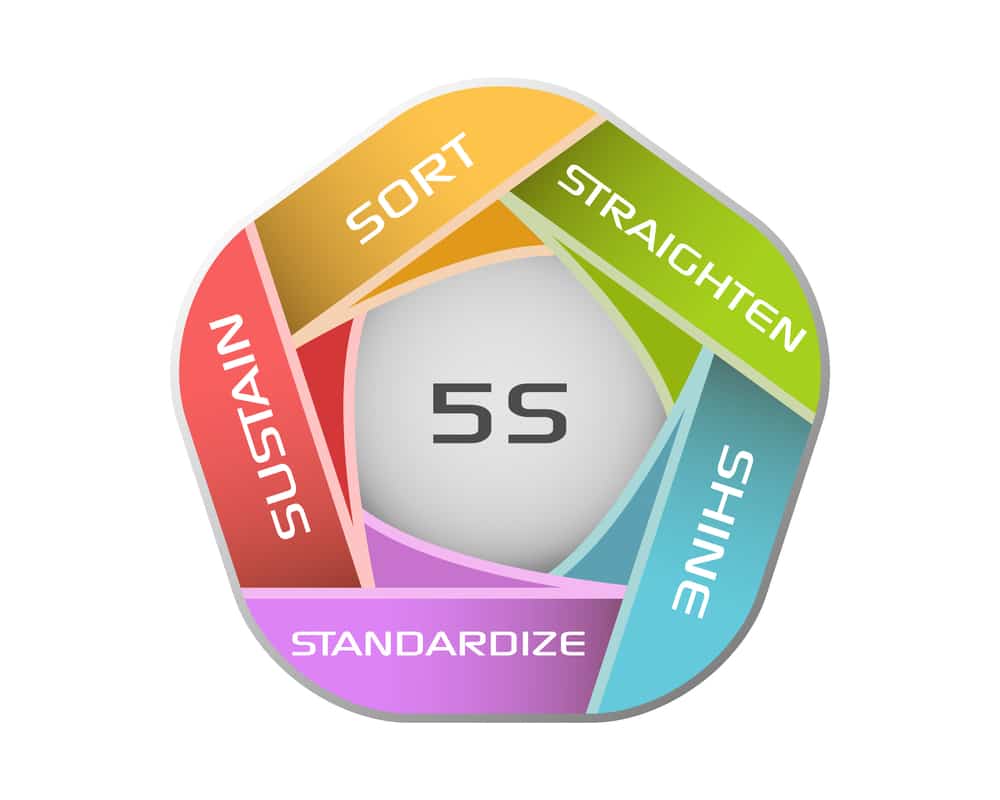

What Are the 5 Housekeeping Rules?

The five housekeeping rules were developed in Japan and are sometimes referred to as 5S, for the Japanese words seiri, seiton, seiso, seiketsu, and shitsuke. A rough English translation is sort, systematize, sanitize, standardize, and sustain.

What Are the 7 Standards for Housekeeping in a Warehouse?

The seven standards, or 7S, are an expanded version of the 5S system. It’s a good framework to keep in mind as you develop your warehouse’s own practices.

1. Sort

Like items should be kept with like items, and, as a general rule, workers should not have to cross the warehouse unnecessarily to collect tools or materials.

2. Systematize

The entire warehouse should have the same cleaning rules and be held to the same cleaning standards. Workers may have different tasks in different parts of the warehouse, but the essential goal is a clean and organized workspace.

3. Sweep

This standard is all about keeping things tidy and hygienic. That means throwing away trash, wiping up spills, and keeping food in designated areas.

Developing a culture of cleanliness can be difficult. But by consistently enforcing cleanliness standards in your workplace, you can help make it an expectation.

4. Standardize

Housekeeping processes should be documented and posted in work areas where possible. These processes can serve as a gentle reminder to staff if they forget how to do a task.

5. Safety

Again, warehouse housekeeping is about more than just cleanliness. Safety should always be the number one concern.

Safety and preventing injuries must take precedence whenever safety and organizational priorities don’t match.

6. Self-Discipline

Housekeeping tasks and standards should be second nature to everyone in your business. From your end, that means plenty of employee education and keeping clear and consistent standards.

7. Sustain

Housekeeping is an ongoing operation, and standards will begin to slip unless you have a plan. Do people know what their tasks are? Do managers or shift leaders have the authority to discipline housekeeping violations?

Keep an open line of communication with your staff – they can let you know what materials they need to keep the warehouse orderly.

Areas to Focus On

Aisles

Maintaining halls and aisles is always a constant struggle for warehouse managers, but it’s absolutely necessary.

Aisles in a warehouse provide the necessary space for people and equipment to move about. But they can’t provide this function if they’re filled with junk.

Pallets and carts should never be stored in on aisle floors and should never block access to fire exits or fire extinguishers.

Combustible materials like wood and cardboard should be kept away from electrical panels and open flames.

Material Handling Equipment

If you have any trucks, lifts, or cranes in your warehouse, you know that this machinery can be dangerous. That danger increases when clutter and poor housekeeping encroach on the space these machines need to function. Understanding the basics of material handling can also go a long way in promoting workplace safety.

Slip and Trip Hazards

Spills, equipment leaks, and dropped objects will happen. If you come across them, try to identify where the leak or item came from and, most importantly, clear the obstruction.

In tight work areas or a space with a high chance of spillage, you should use floor mats to keep floors free of slip hazards.

When in Doubt – Use Common Sense

Train Your Employees

If your staff doesn’t know how to clean and maintain their warehouses, you can’t be angry at them for failing!

Make sure your employees are trained on the following topics:

- How good housekeeping can prevent injuries

- How to dust, sweep, and otherwise tidy the workplace

- Proper maintenance of equipment – where to store and service lifts and trucks

- The proper clothing to wear to work

- Preventing major fire hazards in the warehouse.

Have Cleaning Supplies Easily Accessible

Your staff also can’t clean if they don’t have the tools. Have a clearly marked work area that contains a broom, paper towels, and approved cleaning chemicals.

Have Warehouse Rules in Place

Clean-as-you-go

Unpacking a box? Throw the wrapping and other debris away. Accidentally spill something? Wipe it up before you do anything else.

Having a clean-as-you-go policy helps to make sure that people are cleaning up their own messes and that essential cleaning tasks don’t fall by the wayside.

Create Daily, Weekly, and Monthly Cleaning Tasks

Another good way to ensure accountability for cleaning is to make regular tasks that workers or teams need to complete.

Floors should be swept and dust wiped away daily or even after every shift. Cleaning higher shelves or your storage facilities can probably be done less frequently.

In a spacious warehouse, it’s easy for dead inventory or unused material handling equipment to collect dust. Regularly clearing out unneeded items quarterly or yearly is a basic part of warehouse maintenance.

What Are Examples of Good Housekeeping in a Warehouse?

Good housekeeping looks different in every warehouse, but poor housekeeping is easy to spot.

Poor housekeeping allows workplace hazards to fester, whether that’s loose debris that causes a tripping hazard or improper inventory storage that risks a fire.

When employees aren’t sure of their housekeeping responsibilities or are unaware of important details, that’s poor housekeeping, too.

Teaching your warehouse workers all about Safety Housekeeping is a benefit to everyone. For the employees, it helps reduce injuries and accidents. For the employer, it helps keep the warehouse clean and orderly and helps promote OSHA compliance. We hope these housekeeping best practices help your warehouse employees become superstars of cleanliness!