Asbestos Safe Work Practices – [Updated for 2023]

Asbestos is a blanket term for several fibrous minerals found in serpentine rocks; chrysotile is the only one still in use.

It is durable and resists electricity, fire, heat, and chemical attack. The fibers can be woven, leading to their use in as many as 3000 applications at one stage.

However, asbestos dust poses severe health hazards, and its use is now restricted – learn more about asbestos safe work practices below. We also have an asbestos awareness training course if you are interested in that.

Types of Asbestos-Containing Materials

One cannot visually identify asbestos-containing material (ACM): the fibers are at least 50 times thinner than human hair. Identification requires the use of a polarized light microscope by a trained individual.

However, it is possible to list certain common asbestos-containing materials.

It is found in old fiber cement boards, soundproof ceiling tiles, acoustical plaster, fireproofing materials, thermal system insulation (around pipes, boilers, tanks, and so on), and old vinyl flooring.

Any material with more than 1% asbestos is considered an asbestos-containing material.

The Dangers of Asbestos Exposure

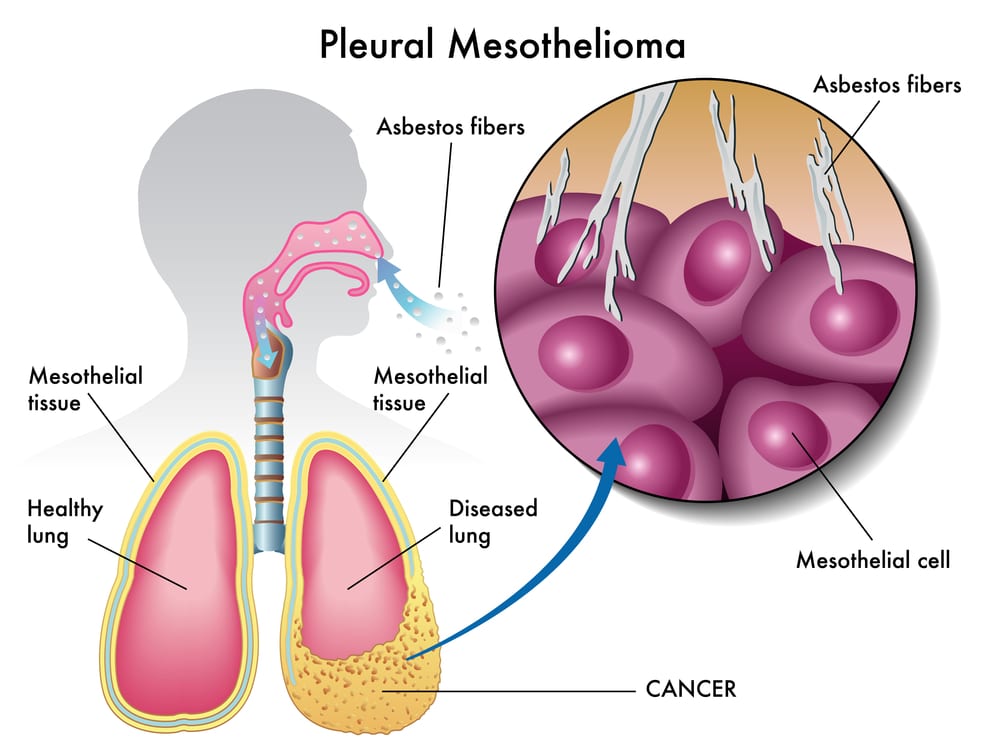

The tiny fibers in asbestos dust (5 micrometers or longer and at least three times longer than broad) make it extremely easy for people to inhale or ingest them.

They lodge in the respiratory or digestive tract and the irritation they cause results in disabling and fatal diseases developing; these diseases only show up some two to three decades after exposure to high levels.

The fibers irritate lung tissue, scarring it, a condition known as asbestosis; this results in chronic shortness of breath and vulnerability to lung infections. Smoking exacerbates this damage: encourage workers who smoke to quit.

Asbestos exposure also increases the risk of lung, laryngeal, and ovarian cancer. It is the only cause of a rare and aggressive cancer known as mesothelioma. That’s why recognizing asbestos in the workplace is so important.

What Professions Are Most at Risk for Asbestos Exposure?

Construction workers, shipyard workers, firefighters, and employees in power plants and factories are most at risk.

Safe Work Practices with Asbestos-Containing Material

The severe health consequences of exposure mean that it is heavily regulated. This regulation has helped to reduce the incidence of asbestos-related diseases.

The Basics of Working with Asbestos-Containing Materials

Any organization that engages in asbestos operations must have an APM (asbestos project manager) responsible for overseeing that employees practice safety when conducting asbestos work.

Basic procedures cover routine operations and maintenance of asbestos-containing material, while advanced procedures contain any large-scale disturbance of ACM in the work area.

The goal of the procedures is to minimize disturbing asbestos-containing materials; which actions to take depends on the risk, i.e., the likelihood of releasing fibers plus the severity of the resultant release.

We can divide ACM into two categories: friable and non-friable asbestos (generally mixed with a hard substance such as cement).

The former can be reduced to dust easily, releasing fibers. The latter resists crushing and is less of a health risk but may crumble with age.

Personal Protective Equipment When Working with Asbestos

Fibers clinging to personal protective equipment (PPE) pose a threat. Protective clothing for asbestos work should, therefore, be disposable.

It should include coveralls that fit snugly at the ankles, wrists, and neck, foot coverings, gloves, and head coverings, made of synthetic that impede the entry of fibers.

If any contamination of workers’ regular clothing occurs, these garments must not be taken home, as this results in a hazard to family members. Vented goggles or face shields should protect employees’ eyes.

PPE is not always necessary for routine maintenance activities, and the project manager should evaluate it on a case-by-case basis.

Any activity likely to result in asbestos levels above those that the Occupational Safety and Health Administration (OSHA) considers permissible must use PPE.

Asbestos jobs performed in a work area with other hazards must include the appropriate personal protective equipment to mitigate those hazards, e.g., protection against falls when working at height.

Proper Respiratory Protection When Carrying Out Asbestos Work

Most asbestos jobs require respirators. Respiratory equipment must provide adequate protection for workers against hazards.

A complete respiratory protection program also includes operating procedures, training in correct respirator use, evaluating the right fit, proper respirator maintenance, routine medical examination of workers, and supervision.

Whether respirator use is administered by the APM or the facility’s overall safety and health officer, the responsible individual must have the proper training and accreditation for this role.

As with protective clothing, respiratory protection is mandated by OSHA regulations when workers face exposure or potential exposure to fiber levels exceeding OSHA permissible levels.

Appropriate Respiratory Protection to Ensure That Workers Are Adequately Protected

Disposable paper dust masks should never be used as PPE when performing work on ACM. Variations of full or half-facepiece air-purifying respirators with replaceable high-efficiency particulate air (HEPA) filters are acceptable.

These filters are 99.97% effective for particles down to 0.3 microns in size and should be changed when increased breathing resistance occurs.

Respirators can either be negative pressure or a powered air-purifying respirator (PAPR) that creates positive pressure in the facepiece. Select respirators approved by the National Institute for Occupational Safety and Health (NIOSH).

Respirators must fit correctly when fitted; negative pressure respirators also require ongoing fit tests.

What Are the Safety Standards for Asbestos?

OSHA has set a permissible exposure limit (PEL) and excursion limit (EL) for asbestos. Although seemingly strict, there is no evidence of any amount of exposure being safe.

How many days per year must workers perform asbestos work? Instead of a limit on the number of days, employers must adhere to limits on permissible exposure.

The OSHA standard requires employers not to allow their workers to be exposed to asbestos more than these limits.

Employees exposed to levels of asbestos material above this limit must have access to a double locker facility: the first change room is to remove contaminated clothing, after which they enter a shower to wash away fibers.

Employees must use the hygiene facilities at the end of a shift. The second changing room is where employees don street clothing before going home.

Employers must also provide lunchrooms with positive pressure filtered air supply where workers can eat and drink.

Employees working with asbestos must wash their hands before eating, drinking, smoking, or applying cosmetics. Smoking in regulated areas is prohibited.

Cleaning of Work Clothing

Asbestos-laden work clothing removed in the appropriate change room must go into closed and marked containers and be transported in labeled and sealed bags that do not permit the passage of fibers.

Workers must receive clean protective equipment and work clothing at least once a week. The employees who launder asbestos-contaminated clothing must be aware of the health hazards of asbestos exposure and how to avoid them.

Building Owner Responsibilities and Obligations

Any building owner must know which materials used in construction are likely to be asbestos-containing materials in any buildings built before 1980.

As building owners, employers are responsible for training employees on handling ACM safely and where asbestos-containing materials and presumed asbestos-containing materials are found in the building.

Owners must record if, where, and how much ACM is in the building for as long as they own it and must transfer these records to any new building owner.

What If I Have Been Exposed to Asbestos at Work?

Employers are responsible for running a medical surveillance program to assess the health of workers exposed to airborne concentrations exceeding the permissible exposure limit.

These medical examinations must be carried out by a licensed physician or at least under the supervision of such an individual. The cost of these medical examinations and procedures must not be charged to the employees.

Employee Training

With yearly refresher training, workers must receive training about safe work practices before working with asbestos.

The training must include the location of asbestos-containing materials and presumed asbestos-containing materials and signs that they are deteriorating. Workers must understand the use, removal, and disposal of PPE.

Workers should also know how to respond to fiber release and be aware that they must not attempt asbestos control or clean-up if they are not appropriately trained.

Training must be clear to all employees – be aware of language barriers.

APM Responsibilities

The asbestos project manager (APM) must test for airborne fibers and institute engineering controls to avert levels higher than are permissible.

This individual must ensure workers are trained and supervised, supervise asbestos control, and issue appropriate PPE. They must also determine when to hire a licensed asbestos abatement specialist.

They must inspect the work area after a job, check that all ACM is correctly labeled, and arrange the safe removal of asbestos-containing waste.

How to Prevent the Release of Asbestos Fibers

Power tools should not be used with ACM, as sawing, sanding, and drilling release dust into the air in the work area.

Workers should not use compressed air to clean ACM instead of wet methods.

Power tools that disturb asbestos fibers are permissible if they have exhaust ventilation equipment incorporating a HEPA filter.

Automotive Asbestos Safe Work Procedures

Mechanics working with friction equipment such as brakes and clutches can achieve asbestos control in the work area by using a negative-pressure enclosure and HEPA vacuum system or a low-pressure enclosure and wet-cleaning.

Automotive workshops, clutch, and brake specialists may use an alternative control method if it demonstrably achieves the OSHA-required permissible exposure levels in the air.

Safe Disposal of Asbestos Waste

The hazardous nature of asbestos means that any waste, whether ACM or contaminated clothing and equipment, must be carefully collected to be taken to the designated landfill sites.

Workers must place asbestos waste into a sealed and impermeable bag or other closed container. Not only should dust be unable to escape the bag, but it should not puncture or tear during typical operational situations.

The OSHA standard requires that waste be double-bagged in 6-mil-thick bags or a single, thicker bag. Employees must label all bags or containers holding asbestos-containing waste as such.

Waste removal should occur frequently; waste should not accumulate.

Asbestos Maintenance Cleaning Techniques

Two particular techniques are used for custodial maintenance of AMC; these are not indicated for responding to large-scale fiber release.

Wet Cleaning

Dry sweeping and dusting cause fibers to become re-suspended in the air, where people can inhale them. Wet methods involve applying water to ACM to dampen the fibers and keep them in place.

Wet-cleaning methods include spraying water at low pressure or using a damp cloth or mop to wipe up fibers from the surface of ACM.

Once the fibers have been gathered, workers must discard this equipment, following the correct procedures for the disposal of asbestos waste while the cloth or mop is still wet.

HEPA Vacuums

A HEPA-filtered vacuum is sometimes better for cleaning up debris than wet cleaning. These filters are fine enough to remove tiny fibers, including asbestos.

The filters in ordinary industrial vacuum cleaners let these fibers pass through and re-enter the air.

Contaminated carpeting, curtains, or other fabrics can be steam cleaned when the work area has minimal occupants. However, removal and replacement are often more cost-effective.

Workers should dispose of the contaminated materials as asbestos-containing waste under supervision by the APM.

Workers emptying HEPA vacuums and changing filters should work in a restricted area and wear appropriate PPE before transferring the debris into bags or containers suitable for disposal.

If custodial workers are not trained to work with ACM, emptying a HEPA vacuum and changing their filters should be the responsibility of trained maintenance workers wearing the correct protective clothing.

Procedures for Fiber Release Episodes

EPA regulations define a “major fiber release” as any incident involving more than three linear or square feet of ACM; these constitute emergencies.

The procedures to follow in the wake of a major release episode vary, depending on the following:

- the site

- the amount of ACM involved

- the extent of fiber release

- the proximity of the release site to the air-handling system

- the accessibility of the release site

Building owners and APMS should obtain input from regulatory officials and consult asbestos abatement contractors to develop strategies for clean-up. Only trained abatement professionals may perform the decontamination.

ACM Contamination of the HVAC System

If ACM is disturbed in an air plenum, the HVAC system can distribute the fibers throughout the building.

Should this occur, one should shut down the system and perform clean-up procedures throughout the building.

The Basic Procedures for Major Fiber Releases

Isolate the area with negative-pressure mini-enclosures to prevent airflow from carrying fibers out of the contaminated area.

Install temporary barriers, close all permanent doors, and post signs immediately outside the restricted area to prevent inadvertent exposure.

Cover all surfaces within an enclosure with impermeable drop cloths; discard these afterward as asbestos waste. Barriers and enclosures should also be disposed of unless they have smooth, impervious surfaces that permit cleaning.

After decontamination, workers must thoroughly clean the area with wet methods and HEPA vacuuming. The APM should perform a careful visual inspection and monitor the air for fibers.

Abatement professionals should also handle minor fiber releases, but these incidents do not require such rigorous containment as major release episodes.

Asbestos Safety: The Bottom Line

Asbestos is a hazardous material, and work practices should always err on the side of caution. Training your employees on asbestos safe work practices is so important.

Implementing higher safety standards keeps workers safe from inhaling hazardous fibers that can cause severe complications, including lung cancer and asbestosis, years down the line. It also protects employers against heavy penalties if they’re found to be non-compliant with safety standards.

Training employees to understand the material’s hazards benefits everyone. Implement company-wide safety training now.