HAZWOPER Engineering Controls and Work Practices Training

$239

Part of any HAZWOPER training needs to include a deeper dive into Engineering Controls and Work Practices. This training video will cover these areas of HAZWOPER and will give your employees a broad understanding of how engineering controls and work practices each fit into the HAZWOPER environment.

This HAZWOPER Engineering Controls & Work Practices Training Covers:

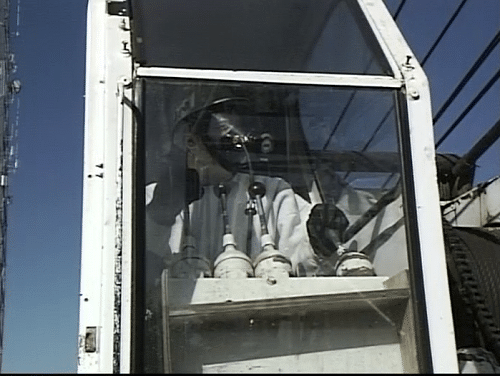

- What are HAZWOPER Engineering Controls, and how do they help keep employees safe who are working with or around hazardous materials? (Engineering controls in a HAZWOPER environment are devices that keep employees away from hazardous materials. Examples of engineering controls are pressurized equipment cabs, ventilation systems, remote-controlled hazardous materials equipment, etc.)

- What are HAZWOPER work practices, what are some examples, and how do they fit into a HAZWOPER program? (Work practices are administrative controls for separating workers from hazardous materials)

- Are there any work practices that are universal and not site-specific? (A few, but since all HAZWOPER situations differ in the chemicals involved, the location, etc., most work practices are very specific to the site in question. These details, and the work practices that apply, are always part of the Site Safety and Health Plan.)

- What are the two major areas the “work practices” section of the Site Safety and Health Plan covers?:

- Procedures for performing specific tasks

- What to do when a HAZWOPER emergency occurs

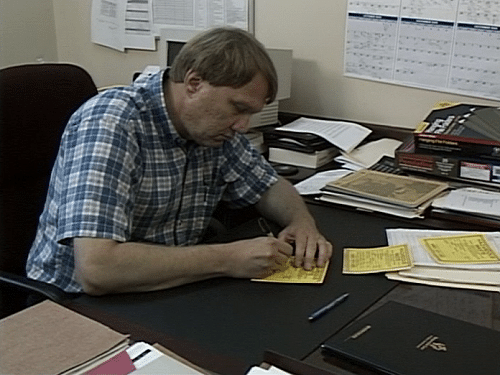

- What is a “Job Safety Analysis” or “Job Hazard Analysis,” and why and when are they used? (These tools are used to determine the risks associated with each of the work activities in a hazmat or HAZWOPER environment)

Additional Topics Covered in the HAZWOPER Engineering Controls and Work Practices Training Video:

- What is the role of a Site Safety and Health Officer?

- What role do hazardous materials experts, chemical guidebooks, and Safety Data Sheets play when establishing emergency response protocols?

- How are ventilation systems used in a HAZWOPER situation? (Ventilation systems are required whenever there are large amounts or concentrations of fumes, vapors, or dust and where air circulation is inadequate)

- What are other examples of engineering controls? (In addition to ventilation, there are eyewash stations, fire fighting equipment, spill cleanup gear, personal protective equipment, and more)

- What role do eye wash stations play in the operation of hazardous materials cleanup, and what are the rules surrounding their placement? (They must meet ANSI/OSHA Standard, they might be no more than 100 feet from a hazardous materials work area and be reachable within 10 seconds. They must produce water flow within one second of being turned on and sustain a water flush for at least 15 minutes on an uninterrupted basis.)

- And much more…

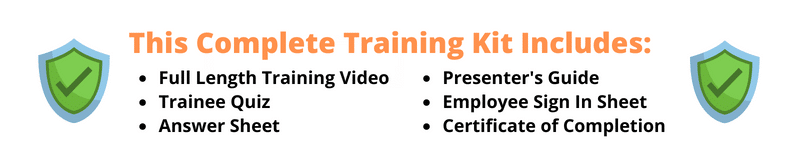

When teaching HAZWOPER principles, you must include the concepts of engineering controls and work practices. Both concepts are important in any HAZWOPER training and hazardous materials cleanup operation. This HAZWOPER Engineering Controls and Work Practices Training Kit gives you everything you need to get these important concepts taught to your crew. Available as an English or Spanish-speaking DVD or USB Stick, the length of this training is 18 minutes.