6 Lockout Tagout Steps – [Procedures for 2023]

Lockout Tagout (LOTO) procedures protect workers when machines and equipment need repair or maintenance. You cannot operate on machinery that is still powered up and running. The Occupational Safety and Health Administration set specific LOTO procedures to ensure residual energy is dispersed properly and doesn’t harm workers.

Following these safety precautions, you can train employees on the importance of controlling hazardous energy to avoid serious injury in the workplace. Review LOTO safety and health procedures before maintenance activities on machines and equipment. These Lockout Tagout Steps will help you do the right thing at the right time. We also offer a full-length Lockout Tagout Training Program if you want to check that out.

The Importance of An Energy Control Program

Lockout Tagout procedures are in place to protect workers from unexpected startup and hazardous energy. Using an energy isolating device, affected employees can stay safe while the machine or equipment is operated on. Your OSHA standard lockout tagout procedure is designed to allow maintenance work by an authorized employee.

The risks involved with ignoring lockout tagout procedures include serious injuries and even death in the worst scenarios. A machine cannot be repaired or maintained without lockout tagout measures, as the mechanisms are not secured and can easily injure workers. Even skilled employees can sustain life-threatening injuries if a machine unexpectedly turns on.

When done in the correct order, lockout tagout procedures can save lives. Train employees on LOTO programs and mechanical safety features to ensure they are prepared for any situation. The following six steps are easy to follow and assure your safety in the workplace when machinery needs to be repaired. Finally, as you know, OSHA does require a full-fledged Hazardous Energy Control Program.

Step 1: Prepare Equipment

According to the Occupational Safety and Health Administration, the first step of a lockout tagout procedure is to prepare yourself and the machine for maintenance activities. This means an authorized employee must identify equipment that needs to be properly isolated due to potential hazards. The employee must investigate the machine or equipment to gain a complete understanding of what energy type is present.

This must be done before any employee attempts to perform maintenance on the equipment. It’s important to identify what the specific hazards are before maintenance activities begin so that maintenance workers are well-informed about the work they will be doing. Knowing what kind of hazardous energy needs to be controlled will determine the best practices for controlling it.

Return controls to their off positions before investigating further to keep yourself from accidentally getting caught in any equipment or mechanisms. You want to check every detail of the machine, including water pressure if applicable, to uncover any problems that need to be fixed. Once this LOTO safety step has been completed, you can move on to the next one.

Step 2: Shut Down the Machine or Equipment

With the planning and preparation phase complete, it’s time to move on. The next step in LOTO safety is to shut down the machine or equipment entirely. Control of hazardous energy cannot begin until after the equipment has been shut off. Ensure the equipment is in the off position before continuing so that no one gets hurt while working on it.

According to the Occupational Safety and Health Administration, you must notify affected employees and equipment operators that maintenance activities are being conducted, even if they are not doing the maintenance or repair work themselves. When you inform employees and machine operators that the machine or equipment is undergoing maintenance, you’re alerting them to the potential hazards they face if they attempt to operate the machinery.

Surely you’ve read more articles or heard horror stories of employees using machines and equipment they thought were safe, only to result in serious injury, like fracturing body parts, or even death when the equipment fails? Don’t let a similar tale weave itself in your workplace! Inform any affected employees to keep them safe from harm during the maintenance period.

Step 3: Isolate Hazardous Energy

The next step involves isolating the machine or equipment from any energy sources it may draw power from. This step is crucial to safeguard employees from dangerous situations before they begin working on the machine. Before using any lockout tagout devices on the machinery, check to see what you can do to disconnect the machinery or equipment from all power sources.

This can range from turning a valve to shutting the energy source off at the breaker. If necessary, block lines to the power sources to keep the equipment shut off and isolated from hazardous energy. Any nearby power source must be disconnected so that it doesn’t provide energy to the faulty equipment.

The important thing is to ensure that the power is entirely cut off from the machine or equipment so that any potential energy sources cannot re-energize the machine while maintenance is being conducted by workers. If this step is missed, the person performing maintenance is placed in a dangerous position.

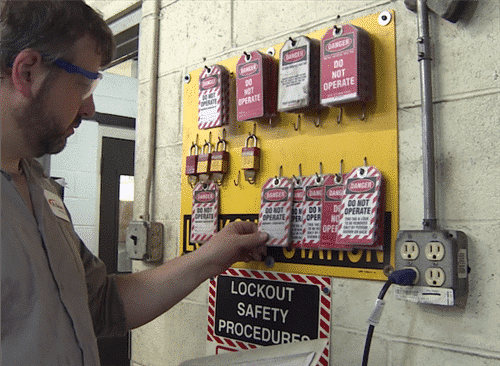

Step 4: Utilize Energy Isolating Devices (Lockout/Tagout)

Now that the machine has been isolated from its energy source, it’s time to move on to the next step in the lockout tagout procedure. This means using one of the lockout devices provided to keep the power from coming back while maintenance is being done.

This step required the employee authorized for maintenance to lock and tag out the machine with the proper device to each energy isolating device so that the machine remains in a safe position. The only operator capable of switching the machine from the safe position to the unsafe position is the one performing the repairs themselves.

While the lockout device is meant to cut off the power and keep it that way, the tagout component of lockout tagout procedures is designed to provide additional information about the repair. The name of the employee conducting the lockout tagout will be present on the tag, along with any relevant information about the problem and maintenance.

Step 5: Stored Energy Check

Once the machine has been secured and power has been cut off from any potential energy sources, and the lockout tagout devices have been applied, it’s time to check for hazardous energy. Even when a machine is shut off and disconnected from any energy sources, the stored energy can create a problem. This residual energy left over from the last time the equipment was operated can cause the machine to restart unexpectedly and cause severe injuries to workers.

LOTO safety protocol requires employees to take control of hazardous energy stored in the machine. If discovered, that energy must be released in a non-hazardous way before continuing so that it does not affect other employees in the area. hazardous energy release requires great care to ensure the safety of the nearby employees.

If the energy cannot be released safely, it must be disconnected, restrained, or made non-hazardous in another way to ensure the safety and health of the maintenance worker before they begin working on the machine.

Step 6: Isolation Verification

The last step in the lockout tagout procedure is to double-check you’ve done everything right. This step is here to guarantee you’ve done everything according to company standards and have ensured that the machine or equipment is safe to begin performing maintenance on. While every machine guards against accidental injury in some way, it’s important to check your work before moving forward.

Verify isolation from the power source. Is the machine unplugged? Is it disconnected from other energy sources? If so, it’s time to determine if the lockout tagout device was applied correctly. Is the LOTO safety device positioned so that the machine is locked in a safe position? Was the tag applied properly according to the lockout tagout specifications?

If the answer is yes, double-check that there is no residual energy stored inside the machine. Open any access panels to assess the state of the machine and release any stored energy that’s built up before moving forward. Never cut corners with LOTO safety and take the time to triple-check if you must before beginning maintenance on machinery.

When to Restore Energy

Once the repairs are complete, it’s time to begin restoring power to the affected machines and equipment. This means removing the lockout tagout device and tags, as well as slowly restoring power to ensure the machine is functioning properly.

This process should not be rushed, as it may reveal other problems that will need to be repaired. Only authorized personnel can restore power to the machines they worked on thanks to the lockout device.

Lockout Tagout Training Programs

While these steps are easy to follow, proper training is recommended and often required for all employees. By outlining protocol in comprehensive modules, employees can educate themselves on the necessary procedures and restrictions meant to keep themselves and others safe.

If you have questions, ask your supervisor! There should be documentation available for you to review about OSHA standards and lockout tagout procedures. You can always revisit training modules if you need a refresher on the best safety practices in the workplace when it comes to repairing and maintaining machinery and equipment.

The Bottom Line

By following these established Lockout Tagout Steps, you keep all your employees safe from the dangers of hazardous energy. Your organizational performance directly impacts how effective the lockout tagout program works and how safe your fellow employees are. Don’t allow workplace injuries to occur when you can execute proper lockout tagout protocol to keep them safe. If you need additional resources you can also check out our Lockout Tagout Toolbox Talk for more information.