How to Write an HACCP Plan – [Updated for 2023]

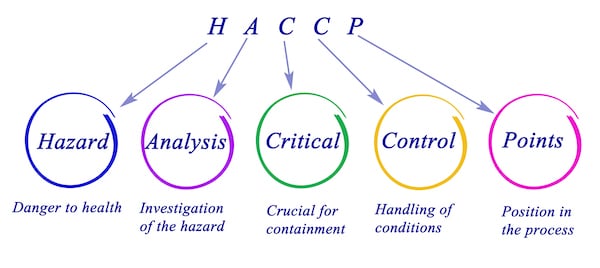

The HACCP Plan is a world-renowned food safety system that outlines strategies for monitoring, preventing, and resolving potential food safety hazards for businesses in every aspect of the food industry.

A thoroughly designed and effective HACCP system is crucial to ensure that any biological, chemical or physical hazards are identified before they contaminate raw materials or other food products.

A facility’s HACCP plan is one of the most essential preventive measures to ensure good food hygiene. In the event that a deviation occurs, the plan will outline the corrective actions necessary to address and resolve the identified hazards, including procedures for safely disposing of any contaminated food products.

Writing a HACCP plan requires specific planning and preparation. An HACCP team must be assembled of employees who are experts in different aspects of the food preparation process. We do offer an HACCP certification training course that can help your staff understand how to put this program into place.

Does your Company want to understand how to write an HACCP plan that will keep your facility on track with food safety? Read on…

Why is Having a HACCP Plan Important?

The HACCP system is designed to avoid adverse health consequences from food hazards and maintain food safety through monitoring procedures, hazard analysis and corrective actions.

Without the guidelines offered by the HACCP plan, facilities may not have appropriate control measures in place, leading to contamination of raw materials, failure to detect food safety hazards, and other serious safety concerns.

Many countries require food businesses to design and implement a HACCP system to identify and prevent any food safety hazard before interfering with the production process. If you are wondering what an HACCP plan costs, we do have some information on that topic as well.

How Do HACCP Systems Prevent Food Safety Hazards?

The HACCP plan works to lower the risk of food safety hazards through hazard identification, critical control points, and the implementation of a detailed monitoring system.

Once all employees have been educated on the facility’s HACCP plan, they will know which corrective actions to take to resolve any hazards identified at a given critical control point.

An effective HACCP system requires all employees in the food business to understand the preventive measures outlined in the plan.

This often necessitates the creation of a flow diagram that demonstrates the food production process and product and process flow at the facility in a clear, easily digestible format.

Preparing to Write a HACCP Plan

Writing a HACCP plan takes dedication and preparation. A number of prerequisite programs must be in place before a HACCP plan can be successfully implemented. The FDA actually has a lot of good information on how to put together a full functioning plan.

Additionally, a diverse and dedicated HACCP team must be assembled to facilitate the writing of the HACCP plan. This team should include employees from every aspect of the production process, not just quality control personnel.

1. Review All Prerequisite Programs

The food business should have all of these programs in place before writing and implementing its HACCP plan. These programs form the foundation of the HACCP system and involve the minimum standards of quality for sanitation design, food safety, employee health and training, and necessary environmental conditions.

Sanitation standard operating procedures

Sanitation is a crucial part of food safety and preventing food hazards. Employees should be thoroughly trained on the food business’s sanitation procedures to fulfill all relevant laws and regulations.

Sanitation design principles

The design of all sanitation procedures and facilities should avoid any risk of cross-contamination with the food processing methods in the facility.

Proper food business layout

The physical design and setup of the facility must be structured to avoid physical hazards such as tripping and dangerous walkways.

The layout should also avoid creating scenarios that increase the likelihood of cross-contamination from biological, chemical, or physical agents during the production process.

Prevalent Food Safety Posters and reminders

Colorful, descriptive food safety posters help employees maintain good hygiene practices. These can include signs about hand washing, reminders about safe storage of cleaning chemicals, and warnings related to minimum safe storage temperatures of raw materials.

Air and water control

The facility should have complete control over the temperature and quality of the air and water inside to ensure proper environmental conditions are met.

Thorough food safety training for employees

All employee training sessions must prioritize thorough food safety training, ensuring that employees understand best practices for food hygiene.

Effective pest control

There must be a demonstrably effective pest control program in place that prevents infestations at the facility while also avoiding any biological, chemical, or physical hazards.

Effective Waste Management

Waste management must be effective and thorough, including septic and garbage disposal.

2. Establish a HACCP Team

The HACCP plan will be designed by a designated HACCP team comprised of employees from various aspects of the food business.

Who Should Be on the HACCP team?

Individuals who thoroughly understand their part of the process, the end product, and the HACCP plan design are good candidates for the HACCP team. The team should be comprised of employees from various departments, such as quality assurance, engineering, managing, logistics, and manufacturing.

3. Outline Basic Information About Your Food Business

Since the HACCP plan is designed to protect food safety at a specific facility, it’s vital to identify the nature of your business, including the process, product, and intended consumers, before outlining your HACCP plan.

Identify your food products

A thorough description of your food product or products will help your team conduct a hazard analysis by giving them an idea of what potential hazards might be involved in the process.

The product description should include the ingredients, food allergens, processing methods, proper storage, physical size and weight, ideal visual appearance, and any other useful information about the product that might aid in the identification of hazards and control measures.

Make sure the details of this product description are very specific. Include the minimum and maximum acidity, water level, temperature, and salt concentration, as well as specifications from your suppliers about the raw materials that come together to create the product.

Identify intended consumers and product use

Knowing which customer base your product is intended to reach can help employees better understand the specific food safety hazards they may need to watch for.

This is especially true if the intended customers belong to a vulnerable or potentially immunocompromised population, such as pregnant people, infants, and people with allergies or other dietary restrictions.

The intended use of your product is also an important factor in hazard identification. Will the end product require further processing at the customer’s home or another facility? Is the product ready to eat as is, or does it need to be cooked?

Answering these questions is a key prerequisite to developing a HACCP plan.

Create a flow diagram for your food production process

Every step of your company’s food process should be mapped in the form of a commodity flow chart. The flow diagram should be comprehensive and detailed, as it will form the basis of an important step in the HACCP plan later.

- The specific steps involved in your company’s production process will vary depending on what the product is.

- For example, the process of creating baby food is very different than the process of crafting frozen dinners or condiments.

4. Confirm and Verify All Preparatory Steps

This step is vital to ensure no mistakes have been made or facets overlooked before writing the HACCP plan. These verification procedures include checking the prerequisite programs listed above to make sure the way has been prepared for the HACCP team to begin their work.

Check the commodity flow diagram to ensure that the entire process has been accurately represented.

Once the flow diagram, prerequisite programs, and other preliminary steps have been verified, the HACCP team can begin writing the HACCP plan.

How Do You Write a HACCP Plan?

The HACCP team you appoint will be responsible for developing a complete and detailed HACCP plan that encompasses and addresses the specific hazards, monitoring procedures, critical limits, critical control points, and corrective actions appropriate for your facility. You can also follow the excellent information that the U.S. Department of Agriculture puts out on how to develop and write your plan.

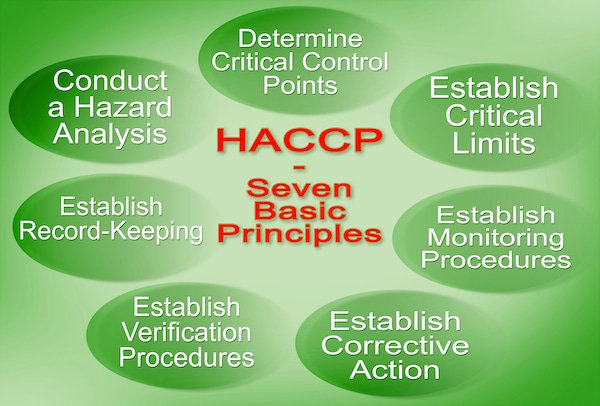

This plan will be comprised of the seven major principles of HACCP. Each principle must be applied to the facility the HACCP plan is being composed for. Attention to detail is critical, along with correctly executing the principles.

The Seven Principles of the HACCP System

Below are the seven writing stages of the HACCP plan. These steps will help your HACCP team come up with a specific HACCP plan for your facility.

1. Identify and Analyze Potential Hazards

Hazard analysis is the first step in designing a HACCP plan. The entire purpose of a HACCP plan is to address hazards before they even happen; therefore, all potential hazards must be assessed and recorded at each stage of the process before the rest of the plan can take shape.

In order to conduct a hazard analysis for food safety, the team must identify all physical, biological, or chemical hazards that may be present.

The next step of hazard analysis involves ranking these potential factors or agents according to the likelihood of contamination, as well as the degree to which contamination could cause illness or injury.

The types of contaminants present in a given food facility vary dramatically depending on the type of food that is processed at that facility. Bear in mind that there might be more than one hazard present at a given stage of production.

Here are some examples of common sources of contaminants that are hazardous for food safety:

- Poor personal hygiene

- Bad cleaning and sanitation practices

- Cross-contamination

- Food allergens

- Improper preparation or handling of raw food items

- Inadequate cook time or temperature

- Improper storage conditions

- Poor or insufficient pest control

- Inadequate packing materials

Once the hazard analysis is complete, the HACCP team will determine the production stages that post the highest risk for contaminants to enter the food products. No other step in the HACCP plan can be written until a thorough hazard analysis of the facility has been conducted.

2. Determine Critical Control Points (CCPs)

After the hazard analysis, the next step for the HACCP team is to identify the critical control points. A critical control point is the step in a food development process at which a specific control measure must be in place to ensure food safety.

Another important factor about CCPs is that they must be stages in the production at which a control measure may be reasonably applied.

Critical control points are the key defense provided by a HACCP plan. The control measure for each point should be set using current best knowledge in food science, as well as best practices for food safety. Physical and chemical methods may be used.

The key to successful implementation of CCPs is that they must be applied to every batch of products. The specific types of CCPs at your facility will depend on what your food company or restaurant does.

Here are some examples of CCPs a hazard analysis team might identify:

- Food receiving and unloading

- Thawing

- Storage, fridge, or freezer conditions

- Washing raw food such as leafy greens before use

- Thermal processing, such as cooking to the correct internal temperature

- Cooling

- Reheating

Not all of these potential CCPs will apply to every food facility; however, they are all key for promoting food safety and continuing the development of your HACCP plan.

3. Establish Critical Limits

The next step in writing a HACCP plan is to establish critical limits for each critical control points. A critical limit includes the highest and lowest acceptable values for a given control factor.

For example, a critical limit could describe the amount of foreign contaminant acceptable in a given batch of food.

Another critical limit is the length of time high-risk food can be allowed to sit outside an appropriately cold or hot storage environment.

If any critical limit deviation occurs, it could result in unsafe food being served or sold to consumers.

Generally, the team will use scientific methods and measurements in order to set critical limits for the HACCP plan. These measurements often involve time and temperature, such as the appropriate length of time to cook poultry and the proper internal temperature of a serving of poultry.

The appropriate critical limits can vary somewhat depending on the type of food being produced. However, a good rule of thumb is that no food should be left at a temperature between 41 degrees Fahrenheit and 140 degrees Fahrenheit.

If any food products have been found to breach the appropriate critical limits, corrective actions will need to be applied to avoid contamination and illness. Therefore, establishing critical limits is an essential part of safety within the food industry.

4. Establish Monitoring Procedures for Each Critical Control Point

Once each critical limit has been established for all critical control points, the next step is to determine the proper monitoring procedures for every point. A properly designed and implemented monitoring procedure can help employees catch hazards before they exceed their critical limits.

Each monitoring procedure should involve written documentation, including a form employees fill out that demonstrates the efficacy of the HACCP plan. There should be a separate, distinct form for every critical control point.

Here is some of the information that may be included on a monitoring procedure form:

- The parameters being monitored

- Any relevant critical limits

- The frequency of monitoring

- The person in charge of the CCP

- Any corrective action taken

Employees should have access to any monitoring equipment necessary to complete their form. This might include PPE, thermometers, logbooks, and writing implements.

If a critical limit occurs, your monitoring system should be able to catch the problem right away, allowing employees to take the relevant corrective action to resolve the issue.

5. Establish Corrective Actions

Monitoring procedures, critical control points, critical limits, and routine hazard analysis are all important strategies for maintaining food safety.

However, unexplained system failure is still possible, even with sufficient validated safeguards in place.

No HACCP plan is totally infallible, which is why corrective actions need to be established that explain what to do in the event of a system failure or if a critical limit is exceeded.

A corrective action is a prescribed method for regaining control over the operation while maintaining food safety to the highest possible degree. Corrective actions are a hugely important part of the HACCP plan because they tell employees exactly what to do when things go wrong.

One example of a corrective action in a restaurant setting is disposing of potentially contaminated ingredients before they get added to a meal. If an employee notices raw meat has been sitting on the counter longer than the critical limits allow, that employee should take the corrective action to throw the meat away before someone mistakenly uses it.

Corrective actions should be documented each time they are used. Record the name of the person who took the corrective action, as well as the reason why the corrective actions were utilized.

6. Establish Verification Procedures

Once corrective actions have been established, the HACCP plan must be verified. This means checking the flow diagram and making sure every step of the plan has been established in accordance with the principles of HACCP.

The HACCP plan must be verified consistently, not just once, to ensure that all steps are working as designed and that no part of the HACCP plan needs to be revised.

Sometimes, an external organization such as the health department or FDA will conduct an audit or health inspection of your HACCP plan. Keeping a thorough record as part of your monitoring procedures will help demonstrate to health inspectors that your business takes food safety very seriously.

Verification procedures can have several steps, including the following:

- Product testing

- Review of the commodity flow diagram

- Evaluation of CCPs and critical limits

- Review of monitoring records

The HACCP plan should always be updated to reflect our current best understandings in the world of food science and food safety. Critical limits may need to be reevaluated as new scientific data is produced.

Ultimately, a HACCP plan is designed to create and maintain an environment that is capable of producing safe food, so keeping up-to-date on current best practices and food safety information is a vital component of verifying the HACCP plan.

7. Determine Recording and Documentation Procedures

Documentation is a key aspect of every HACCP plan. From complete flow diagrams to monitoring records and logbooks, every stage of the HACCP plan should be documented on an ongoing basis.

Proper recording includes making a note of every deviation, corrective action, revision, employee training, certification, calibration record, and verification report. Include relevant dates and names of employees wherever applicable.

Your records should also include a detailed map of the layout of your facility, including information such as where the fire extinguishers and exits are.

Keeping thorough documentation is a way to demonstrate the effectiveness of your HACCP plan, and it shows that your HACCP team is fulfilling its role.

In the event that clients get sick from food served or sold by your facility, you will be able to point to your HACCP plan to show authorities that you and your company take food safety very seriously.

In order to make record-keeping as straightforward and uniform as possible, consider having a set template for every type of record. That way, employees can simply update the template with relevant information rather than trying to figure out for themselves what to record.

The Bottom Line

Food safety is a vital aspect of public health. Any business that operates at any stage of food preparation must have a plan in place to avoid health hazards.

As an international standard in food safety guidelines, the HACCP system offers a clear and thorough method for identifying and analyzing food hazards and placing operations in place that will eliminate or at least dramatically reduce the risk of said hazards.

A HACCP plan is a vital document for businesses to demonstrate their commitment to food safety and to controlling hazards that could make their customers ill. It’s also useful for keeping all employees on the same page about proper food safety protocols in their workplace, including safe food handling practices.

Without a HACCP plan in place, your business could suffer serious losses in revenue and client trust due to health hazards and outbreaks of food-related illness as a result of consuming your products.

Everyone at every stage of the food production chain benefits from the food safety guidelines outlined and maintained by a well-implemented HACCP system, including suppliers, factory workers, servers, and consumers.