11+ Best Fall Protection Safety Tips – [Updated for 2023]

Knowing how to protect yourself from a fall can greatly reduce fall risks in the workplace and protect workers on the job. By learning safety protection tips, you can put a fall protection plan in place to keep workers from serious injury or worse. By complying with OSHA regulations, you’ll create a safe working environment for everyone. These Fall Protection Safety Tips are a good complement for any fall protection training video or other materials that you share with your staff.

Fall Hazards

Identifying fall hazards in the workplace is necessary to keep employees safe. In the construction industry, these fall protection safety tips can save lives. One thing to look out for is an unprotected edge, meaning an edge not blocked off by a guardrail or warning line.

In this situation, the potential hazards include walking off the edge without looking or tripping and stumbling over the edge. Both can result in severe injury or even death, depending on the height of the fall. Recognizing a fall hazard can help implement safety precautions.

Additionally, improper ladder usage can be a fall risk as well. Proper training on workplace safety precautions can prevent falls and keep workers safe.

What are the 4 Types of Fall Protection Equipment?

New workers may not be aware of the systems and equipment in place designed to protect them. Current workers may need a refresher course in fall prevention training from a qualified person on the job site. OSHA requires that all workers are provided with an updated training session when regulations change to ensure their safety.

Listed below are the four methods of fall protection that utilize OSHA standard-regulated equipment. Knowing these will provide a better understanding overall of how working conditions should be and where they can be improved regarding employee safety.

Personal Fall Arrest Systems

A safety harness is one type of personal fall arrest system. Sometimes these involve an anchor point or a dorsal ring (d ring) to steady the full body harness to the floor so that, in case of a fall, you are protected. Employees’ safety is the top priority in construction, so extra equipment that’s used to keep them safe is essential. This specialized equipment might include a body belt or harness, anchorage, connectors, lanyards, a lifeline or deceleration device. We have a whole write up on lanyards for fall protection so you should give that a look as well.

Whether you’re working from a lift or near a floor hole, a body harness will keep you from tumbling down and getting hurt on the job. In addition to other equipment, your fall risk decreases greatly if used with proper training. OSHA regulations require safety equipment for workers operating more than six feet off the ground.

Guardrails

The general industry uses guardrails to block off unprotected edges, whether it’s on the side of the road, a construction site, or a scaffold. A guardrail can often be the first line of defense against construction industry falls, standing almost four feet tall by OSHA regulations to keep you and your coworkers from stumbling over the edge by accident.

Guardrails help employees work safely by clearly marking the edge of a platform or working zone instead of risking the employees stepping off the edge or backing over it when moving around.

Deceleration Device

This piece of safety equipment is part of an excellent fall protection plan that acts fast as a fall is occurring. The deceleration device works with an anchor point to slow the fall and absorb the force that would otherwise impact the employee. Dissipating the force of a fall keeps employees safe, allowing them to fall without risking potentially fatal consequences due to a sudden stop.

Safety Nets

Working at a greater height requires proper training, and employers must include safety nets as a fall protection measure in areas that require it, such as bridges. The nets prevent co-workers from plummeting off the bridge or scaffold in areas where a harness or other device would not be compatible.

What are 10 Good Fall Protection Safety Tips?

For a general idea of what fall protection tips can help keep you and your co-workers from harm in the workplace, these fall prevention tactics are the first steps. Following these guidelines will help you gain a better understanding of fall protection and set routines that align with worker safety.

1. Use Proper Personal Protective Equipment

Adequate training will inform every worker of the proper PPE they should use on the job. Employers are required to provide PPE, which includes fall protection equipment that minimizes risk on the job site.

For instance, construction sites generally require hard hats and reflective vests for safety. The hard hat prevents debris from damaging your head and the reflective vest makes it easier to see you. No matter how experienced you are, everyone from a new hire to a professional engineer must use PPE.

2. Inspect Personal Protective Equipment

As for fall protection safety tips, any damaged PPE must be removed immediately to prevent others from using it and getting hurt. For example, OSHA rules indicate that damaged welding leads shouldn’t be repaired because of safety concerns.

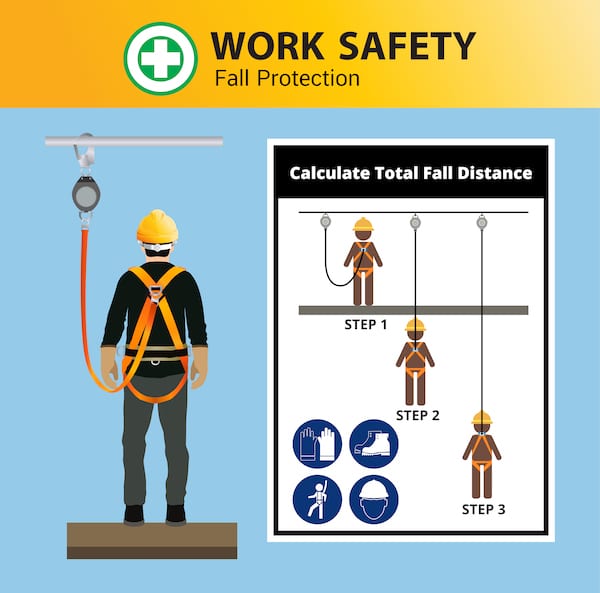

3. Understand Fall Distance

Along with other safety tips, understanding fall distance ranks highly. Job safety analysis includes knowing that there is no “small fall” when it comes to workplace safety. Even a seemingly small stumble can cause sprained joints, broken bones, or concussions. Knowing and understanding the risk that comes with heights and falls will help create safe behaviors.

4. Use Railings

Even when it seems redundant, using railings is a vital aspect of fall protection equipment. A leading cause of workplace injuries is fall incidents, which means taking preventative action to keep workers from harm can reduce the risk. Following OSHA standards, a railing can keep employees safe even if it’s bumped into.

5. Use Proper Equipment for Heights

There’s a difference between a ladder, a scaffold, and a lift. Using the appropriate fall protection equipment is essential to fall protection safety.

6. Use Ladders Safely

Stand clear while a ladder rises, and never use the top step. These are traditionally well-known steps that some people ignore, but they are in place for a reason. Accidents happen where ladders are involved, and taking a little more time to get the job done is worth avoiding catastrophe.

Reading the instructions on the ladder is key to fall protection safety as there are warnings about the dangers of using a ladder without proper technique. Keep your co-workers and yourself safe from unnecessary harm.

7. Understand How Lifts Work

Understanding how a scissor or aerial lift works is essential as well, similar to the importance of PPE and ladders. As a scissor or aerial lift moves around and elevates a worker, knowing how to stay safe in the basket is vital. There’s no room to goof off in construction, and being conscious of the risks will help you stay safe.

8. Know What Fall Protection is Needed

Every situation is different, but the equipment designed for safety remains consistent. Don’t ignore the training you received for convenience. Taking a few extra minutes to equip yourself with the right tools is worth it. If a fall doesn’t happen, you know you are safe. Don’t let yourself fall short of workplace safety standards.

9. Secure Stable Anchor Points

Always secure your anchor points when working with a safety harness–especially when working from heights. Don’t assume that the three points system is functioning without examining it for yourself. Sometimes, in haste, they aren’t properly secured, which puts you at risk of falling and sustaining a severe injury.

10. Practice, Practice, Practice

As with all the aforementioned fall protection safety tips, practice will create the necessary routines to ensure the employees’ safety in the workplace. These measures can be implemented overnight, but maintaining steady execution of these tips and practices takes work.

Feel free to discuss safety concerns with other workers and remind them of safety procedures if you notice them cutting corners. There are no shortcuts when it comes to your safety. What they do will affect you, too.

What is the basic rule for fall protection?

Every employee should know they are safe and not risking a life-threatening injury if they drop through a hole or stumble over an edge. It’s the employer’s job to provide safe workplace conditions.

What is the most effective fall protection strategy?

The most effective strategy is preparedness. Prevention is key to keeping everyone safe on the job and eliminating the chances of an injury. Taking an extra few minutes before starting to prepare for the worst improves the odds that it won’t come to pass. If it does, you’re prepared with the tools and knowledge to minimize the impact.

Review safety manuals and training when you need to so you can stay up to date on the latest safety procedures.

Conclusion

Preventing slips and falls can be done by following a few simple steps and ensuring every employee utilizes their PPE in their working environment. While accidents happen, you can reduce the chance of them occurring in your place of work by staying vigilant. Following the Fall Protection Safety Tips will keep your employees safe and will help keep you in Regulatory Compliance.