Lockout Tagout Training – [Complete Video Kit]

$229.00

If you need a lockout tagout safety video that is OSHA compliant on lockout tagout procedures, then this video is for you! Proper lockout and tagout processes and procedures are necessary for workplace safety. This is especially true for manufacturing or industrial settings where heavy machinery is a part of everyday life. This Lockout Tagout Training Video is intended for both “affected” and “authorized” employees to teach proper techniques and procedures to ensure safe and efficient lockout tagout procedures.

Topics Covered in this Lockout Tagout Training:

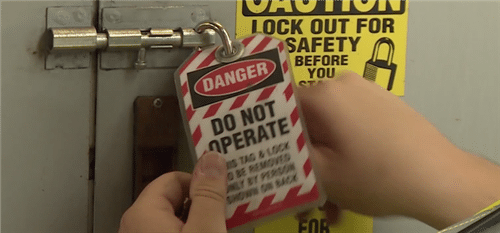

- What is lockout tagout?

- How is a hazardous energy source as defined by OSHA? (What are the key components of OSHA 29 CFR 1910.147)

- What are the dangers to employees for not following sound lockout tagout procedures and best practices?

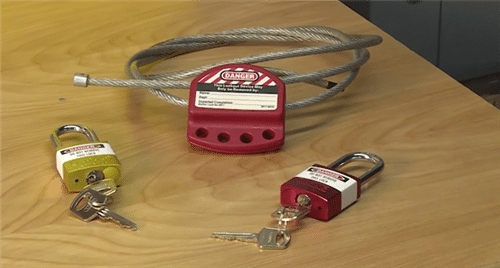

- What are the different lockout tagout devices, and how are they used?

- Padlocks

- Chains

- Valve Clamps

- Wedges

- Pins

- What are the proper procedures to lock out and tag out a machine?

- What are the training requirements for authorized and affected employees under a LOTO program?

- What is an “affected” employee in the eyes of OSHA?

- How does OSHA define an “authorized” employee?

- What are some examples of times that lockout tagout needs to be implemented before working on a machine:

- Repairing circuits

- Cleaning, lubricating, maintenance, and repair of an energized machine

- Clearing jams with the machine

- Rebuilding equipment

- Setting up a new machine

This Lockout Tagout Training Video Also Teaches:

- How does OSHA define an “energy control program?”

- What two components must be included in a written lockout tagout program:

- Answer: Lockout tagout procedures for every piece of energized equipment or machinery within the facility

- Answer: A written plan for training employees on proper LOTO procedures for each of those pieces of equipment

- What specific information needs to be included on the tag of a locked out machine?

- Who provides the locks, tags, and other equipment to employees for use in the employer’s written hazardous energy control plan?

- What are other lockout tagout tips and best practices?

- How to identify all of a machine’s energy sources and ensure that energy isolation is achieved

- Can just any employee remove a tag or lock on a machine that is out of service?

- What type of employee is allowed to restart or re-energize a machine that has been locked and tagged out?

- What are the most common types of energy used to power machinery:

- electrical

- pneumatic

- hydraulic

- What is the difference between “active” and “stored” energy?

- What is a “zero energy state” and why is it critical to safety?

- How is energy dissipated on a machine that has been de-energized?

- What are “special situations” that require additional procedures in your hazardous energy control program?

- What role do arc flashes play, and what are the dangers of arc flash?

- and much more…

A strong lockout tagout video is an important piece of any lockout tagout program, and this LOTO training will help you maintain OSHA compliance and help keep your employees safe on the job. The training is centered around the concepts found in the OSHA Standard for Lockout Tagout. Our lock out tag out training video is 22 minutes long and is available in either English or Spanish language options, and will be delivered either as a DVD or USB Stick. We also offer this training online, either as a standalone training or as part of a larger safety training library.

This Complete LOTO Training Program Includes These Items:

- Full-length Lockout Tagout safety training video

- Employee quiz and answer sheet

- A “Presenter’s Guide” if you are going to do this training in person

- A printable training sign-in sheet to keep track of your training program

- A printable Certificate of Completion. You can print as many copies of the Certificate as you need

Lockout Tagout Training Video – Full Length Preview:

FAQs on LOTO Training

Answered by our in-house OSHA Authorized Trainer – Jason Hessom

Have a question for us? Give us a call at 800-859-1870 ext 2 or, Contact Us Via Email

OSHA states under OSHA 29 CFR 1910.147(e)(3) that any lockout device must only be removed by the authorized employee who put it in place. However, if that employee is not available, in limited circumstances, it can be removed by another authorized person.

Examples include chemical, nuclear, electrical, thermal, pneumatic, mechanical, and hydraulic.

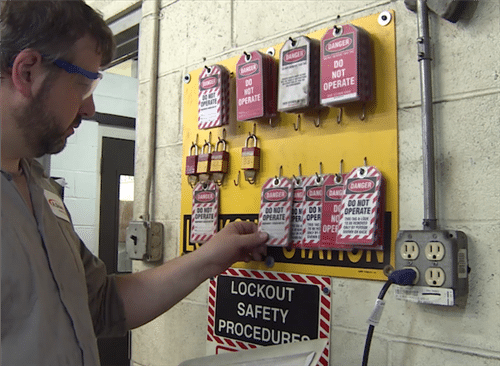

1) Preparation – the authorized employee must understand the machine they are working with and know how the hazardous energy must be controlled

2) Shutdown – Turn off the equipment that is to be worked on and notify affected employees about the shutdown

3) Isolation – Any source of energy to the machine, such as electricity, thermal, pneumatic, hydraulic, or any other type of hazardous energy, must be disabled

4) Apply the Lockout Tagout Device and Tag – This is where the source of energy is “locked out” in a safe “off” position, and then the tag is applied to indicate who placed the tag

5) Stored Energy Check – Any “stored” or “residual” energy must be released

6) Verification – The authorized employee verifies that the machine is free of hazardous energy, locked and tagged, and will not be a source of harm to the person working on it.

After receiving initial training, employees should be retrained and re-certified when:

1) their job requires a new or different lockout tag procedure

2) Any change in equipment, tools, or machines that might present new risks

3) If a near-miss or accident occurs

4) If employees are not following your Company’s energy control procedures or protocols

All of our training videos include the following additional resources:

1) A Leader’s Guide

The person giving the training can use the Guide to help facilitate the training and provide additional verbal support to the video. It also includes a sample outline for the training session along with the highlights of the course.

2) An Employee Quiz

Important to be able to test your trainees to make sure they understand and comprehend the training course they just watched. This is also good for employer documentation for safety training of employees.

3) Answer Key to the Quiz

Ensures the questions are being answered correctly.

4) An Attendance Sheet

Allows you to keep track of who was trained, when the training occurred, who was the instructor, etc. Excellent documentation to prove your training requirements are in order.

5) A Printable “Certificate of Completion”

Allows you to give one to each employee who attends the safety training session. Can also be kept in an employee file for training documentation.

Purchases made before 7:00 pm EST will be shipped out the same business day!

You will receive a tracking number for your package via email within a few hours of placing your order. Shipping is a flat $12.00.

17 reviews for Lockout Tagout Training – [Complete Video Kit]

![Lockout Tagout Training - [Complete Video Kit]](https://www.safetyvideos.com/wp-content/uploads/2022/02/products-20-2-150x150.png) Lockout Tagout Training - [Complete Video Kit]

Lockout Tagout Training - [Complete Video Kit]

My team thought this was good. Also, the price was right compared to other products we looked at and considered. You also get the quiz and other documents so this package is very thorough.

Makes the complex process of lockout tagout easy to understand.

Clarifies lockout tagout procedures for my maintenance crew. A must-have for safety.

Useful for my staff.

A lifesaver for our maintenance team. Clear and effective.